How Do FR4 sheet Work

Time of issue: 2025-09-12

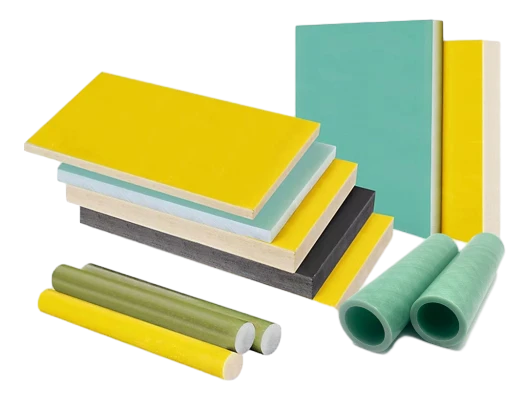

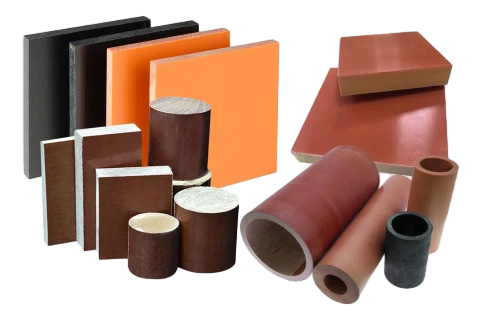

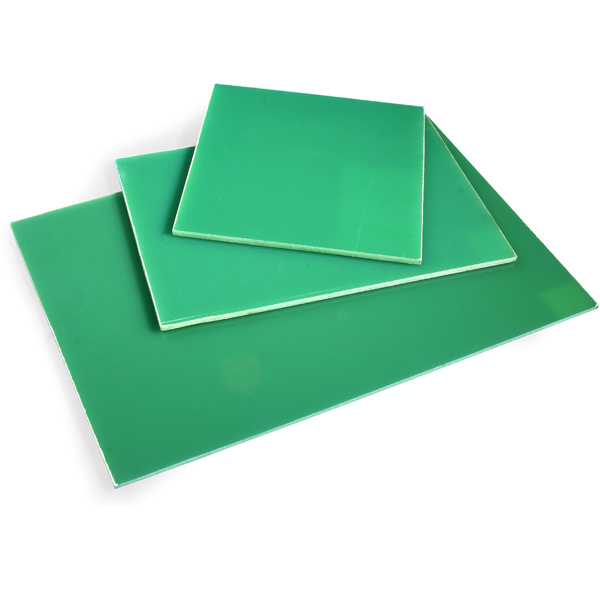

Composite material FR4 is an essential epoxy-glass fiber composite insulation substrate, made by laminating woven glass fiber cloth with epoxy resin under high temperature and pressure to form a strong and stable board.. It is widely used in specific industries today, such as electronics, communications, and electrical engineering, and has good electrical properties, mechanical strength, and somewhat good heat resistance. How then does the FR4 sheet work? Its fundamental working principle depends upon electrical insulation and good heat resistance, and flame retardancy. These properties prevent instability and ensure the reliability of equipment in harsh environments.

1. Structural and Composite Properties

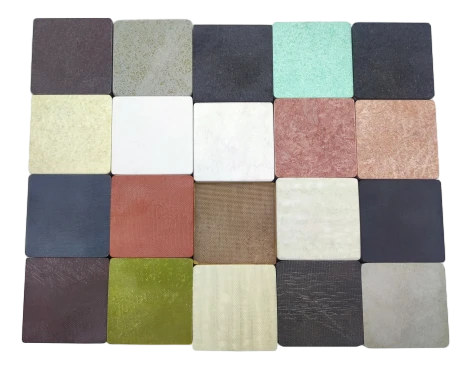

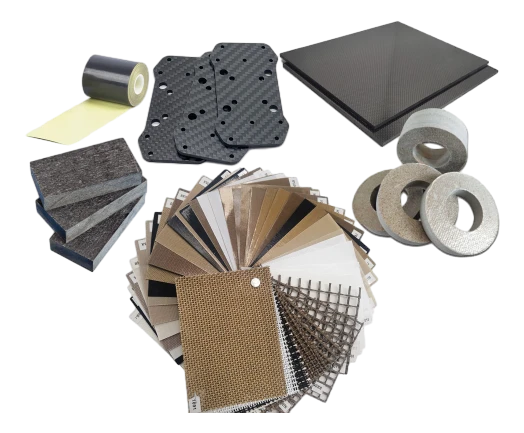

The exceptional performance of FR4 sheet material stems not from a single component alone, but rather from the synergistic effect of its epoxy resin and glass fiber. The epoxy resin, acting as a binder, provides excellent electrical properties, chemical resistance, and flame retardancy, while the glass fiber imparts high mechanical strength and a low coefficient of thermal expansion. It is this unique composite structure that gives FR4 its exceptional overall performance, adapting it to diverse industrial needs.

2. Heat resistance.

It resists deformation or degradation when cast into a design for some prolonged period of time at high temperatures (Between -40°C and 130°C) while still retaining its structure and performance, hence being in wide usage as insulation in equipment requisite for high temperature resistance.

3. Electrical insulation.

Being a material with a low dielectric constant (usually between 4.2 and 5.0) and a very high electrical insulating resistance(≥10¹³ Ω·cm), the FR4 epoxy fiberglass sheet prohibits any leakage currents or short circuits, thereby ensuring safe and stable operation of circuits. It is mainly used in manufacturing printed circuit boards (PCBs) and is widely used as an electrical insulation part in electronic devices.

4. Excellent Corrosion Resistance

The FR4 Board product is attacked by very few chemicals and can, thus, be deployed in a wide range of aggressive industrial environments. Its smooth surface and very little moisture absorption guarantee stability and longevity of service even under humid or chemical environments.

5. Excellent Process Ability

It is capable of being processed into an array of complex shapes by cutting, drilling, and stamping so as to satisfy the requirements of various electronic devices and electrical components. This feature of granting flexibility to FR4 results in its wide application in diversified industrial fields and, consequently, a quick response to various technical requisites.

The diverse applications of FR4 sheet material stem directly from its unique combination of properties, each tailored to meet specific industrial needs. In PCB manufacturing, its low dielectric constant ensures signal integrity, while its excellent process ability allows the creation of complex circuit patterns. In transformer insulation layers and bobbins, its high electrical insulating resistance and good heat resistance enable it to withstand the operating temperatures and electrical stresses of transformers. In high-frequency microwave circuits, its stable dielectric characteristics minimize signal loss, making it ideal for precision high-speed signal transmission.

Previous

More Information

2025-09-12

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com