What Exactly Is a 3240 Epoxy Fiber Glass Sheet

Time of issue: 2025-09-05

In industrial manufacturing and daily life, we often come across various material names. In both areas, "3240 Epoxy Fiber Glass Sheet" sounds professional and foreign. So, what really is this material, and what role does it really have in our production and daily lives?

Definition:

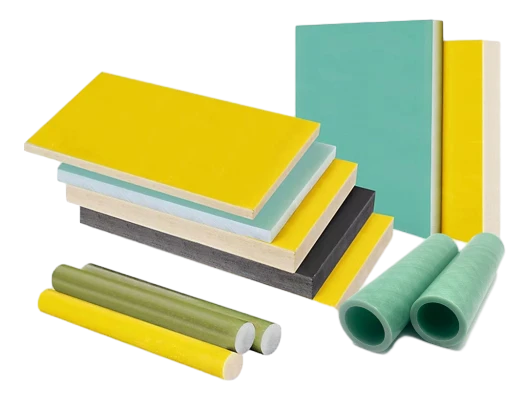

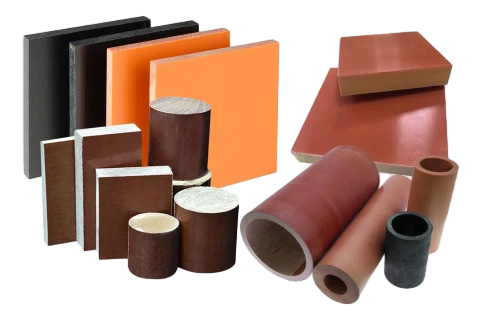

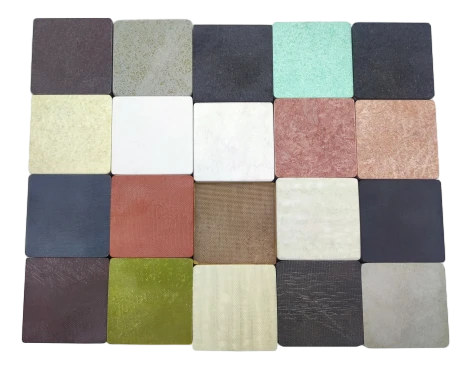

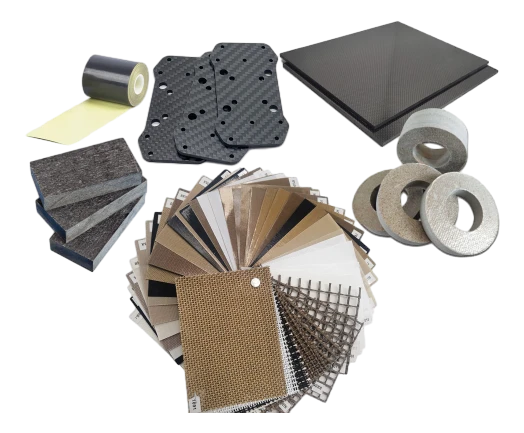

First comes the "3240," which is the national standard designation for this material, being one of the epoxy resin laminates. An epoxy resin is a very common polymer material with superior corrosion and insulation properties. Fiberglass cloth, on the other side, is a reinforcing material woven from fine glass fibers, having high strength, is very stable, and resistant to deformation. When epoxy resin and fiberglass cloth are combined and pressed, we create what people call a 3240 Epoxy Fiber Glass Laminated Sheet.

Good heat resistance is one of the main features of the 3240 epoxy fiberglass sheet. It can be used for long periods below 155°C without any loss of mechanical strength. Good electrical insulation properties have made it widely used in motors, transformers, and electrical switches. Furthermore, its mechanical strength is high, so it can bear certain pressure and impact as a structural component. Compared with ordinary plastic or wood materials, the 3240 sheet is very good as far as safety and reliability are concerned.

Application Industries:

From an application perspective, this material is practically ubiquitous. For example, in the electrical industry, Epoxy Fiberglass Laminated Sheet is often used as motor slot wedges and electrical insulation spacers. In the machinery industry, it can be processed into gears, molds, and fixtures. Even in emerging industries, such as new energy and electronic equipment manufacturing, 3240 Epoxy Sheet plays a critical supporting and insulating role. It can be said to be both an "invisible hero" and a foundational material for modern industry.

Finally, many may be concerned about whether this material poses a risk to the environment or the human body. A 3240 Epoxy Sheet is subjected to safe handling under normal use. However, there may be dust generated from cutting and processing, which may be irritating. So, precautions must be taken while producing and processing it. Having gained more interest and awareness about the environment, manufacturers now upgrade their processes to be environmentally friendly. Hence, 3240 Epoxy Fiber Glass Sheet is not just a cold material term, but a requirement for high-performance materials as modern industrial development demands. Have you noticed that it's already quietly appearing in the electrical devices you already use?

More Information

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com