Why G10 FR4 Sheets Are Essential for Modern Construction

Time of issue: 2025-08-10

Why G10 FR4 Sheets Are Essential for Modern Construction

Table of Contents

- Introduction to G10 FR4 Sheets

- What Are G10 FR4 Sheets?

- Key Properties of G10 FR4 Sheets

- Applications of G10 FR4 Sheets in Construction

- Advantages of Using G10 FR4 Sheets

- Comparative Analysis with Other Materials

- Sustainability and Environmental Impact

- Future Trends in the Use of G10 FR4 Sheets

- Frequently Asked Questions

- Conclusion

Introduction to G10 FR4 Sheets

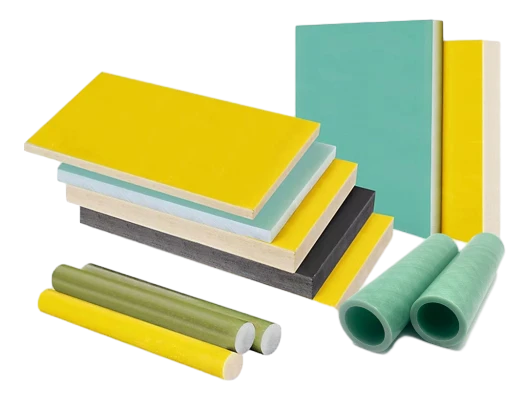

In the realm of modern construction, the selection of materials plays a pivotal role in ensuring durability, safety, and aesthetic appeal. One material that has gained prominence is G10 FR4 sheets, known for their exceptional strength and versatility. G10 FR4 sheets are a type of fiberglass laminate that boasts a myriad of applications, particularly in settings where resilience and electrical insulation are paramount.

What Are G10 FR4 Sheets?

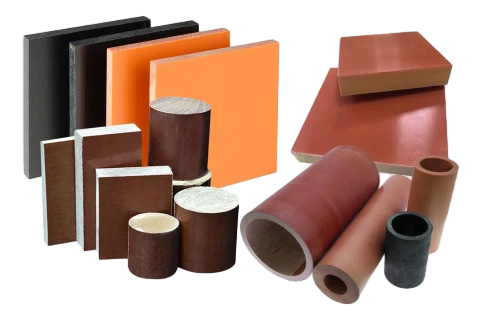

G10 FR4 sheets are composite materials made from woven fiberglass cloth that is impregnated with epoxy resin. This combination results in a rigid, strong, and lightweight material. G10 is a grade designation indicating the specific properties of the laminate, while FR4 denotes its flame-resistant characteristics. These sheets are not only robust but also exhibit excellent insulation properties, making them ideal for various construction applications.

Composition and Manufacturing

The manufacturing process of G10 FR4 sheets involves layering fiberglass fabric and saturating it with epoxy resin. The layers are then cured under heat and pressure, resulting in a dense and durable final product. This meticulous process ensures that G10 FR4 sheets maintain their structural integrity even in demanding environments.

Key Properties of G10 FR4 Sheets

The appeal of G10 FR4 sheets lies in their outstanding properties, which include:

1. High Strength-to-Weight Ratio

G10 FR4 sheets possess a remarkable strength-to-weight ratio, making them suitable for applications where weight reduction is crucial without compromising structural integrity.

2. Electrical Insulation

These sheets are excellent electrical insulators, which makes them ideal for use in electrical enclosures, switchgear, and other applications where electrical safety is paramount.

3. Chemical Resistance

G10 FR4 sheets exhibit resistance to a wide range of chemicals, including acids and alkalis, ensuring longevity in environments where exposure to harsh substances is common.

4. Thermal Stability

They can withstand high temperatures without deforming or losing their properties, which is vital for applications exposed to heat.

5. Flame Resistance

As indicated by the FR4 designation, these sheets are flame resistant, providing an additional layer of safety in construction projects.

Applications of G10 FR4 Sheets in Construction

The versatile nature of G10 FR4 sheets enables their use in various construction applications:

1. Electrical Insulation Panels

In electrical installations, G10 FR4 sheets serve as insulative barriers, protecting wiring and components from heat and moisture.

2. Supports and Mounting Blocks

These sheets can be cut and shaped into supports or mounting blocks for different construction elements, ensuring stability and safety.

3. Structural Components

G10 FR4 sheets are increasingly used in structural applications where lightweight yet strong materials are required, such as in bridges and buildings.

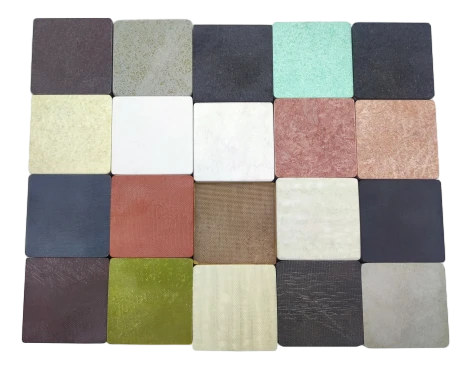

4. Decorative Elements

With the ability to be fabricated into various forms, G10 FR4 sheets can be used in architectural designs, serving both functional and aesthetic purposes.

Advantages of Using G10 FR4 Sheets

The many benefits of G10 FR4 sheets make them a superior choice in construction:

1. Cost-Effectiveness

While initial costs may be higher than some traditional materials, the durability and low maintenance requirements of G10 FR4 sheets save money in the long run.

2. Versatility

G10 FR4 sheets can be tailored to meet specific needs, from thickness to size, making them a flexible option for various projects.

3. Enhanced Safety

Their flame-resistant and insulating properties contribute to a safer construction environment, reducing the risk of fire and electrical hazards.

4. Easy Installation

G10 FR4 sheets are lightweight and can be easily cut and shaped, simplifying the installation process compared to heavier alternatives.

Comparative Analysis with Other Materials

When comparing G10 FR4 sheets to alternative materials commonly used in construction, it becomes evident that they offer distinct advantages:

1. G10 FR4 vs. Plywood

While plywood is a popular choice for many construction applications, it lacks the flame resistance and chemical stability that G10 FR4 sheets provide.

2. G10 FR4 vs. Aluminum

Aluminum is known for its lightweight properties but does not offer the same level of electrical insulation as G10 FR4 sheets, making G10 a better choice for electrical applications.

3. G10 FR4 vs. Traditional Plastics

Many traditional plastics can warp or degrade under heat; G10 FR4 sheets maintain their integrity in high-temperature situations, providing a safer option.

Sustainability and Environmental Impact

As the construction industry increasingly shifts towards sustainable practices, G10 FR4 sheets stand out due to their longevity and low maintenance requirements. While the production of G10 FR4 involves energy, its extended lifespan reduces the need for frequent replacements, minimizing waste. Furthermore, advancements in manufacturing processes aim to reduce the carbon footprint associated with fiberglass production.

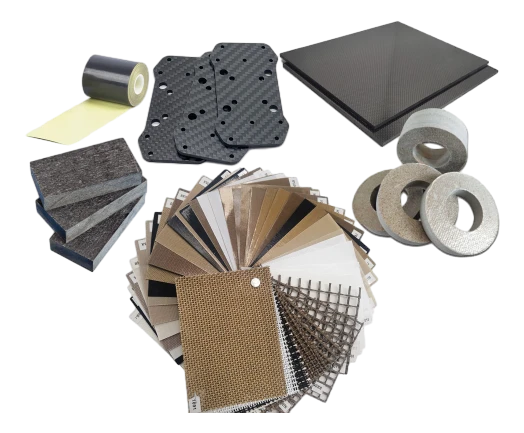

Future Trends in the Use of G10 FR4 Sheets

Looking forward, the demand for G10 FR4 sheets is set to rise as construction evolves. New technologies, such as 3D printing, may enable more complex and innovative applications of G10 FR4 sheets. Additionally, as energy efficiency becomes a priority, their insulating properties will be increasingly sought after in energy-efficient building designs.

Frequently Asked Questions

1. What are G10 FR4 sheets used for?

G10 FR4 sheets are used in electrical insulation, structural components, decorative elements, and as mounting blocks in construction.

2. Are G10 FR4 sheets environmentally friendly?

Yes, while their production does consume energy, their long lifespan and low maintenance needs contribute to reduced waste.

3. How do G10 FR4 sheets compare to traditional materials?

G10 FR4 sheets offer better flame resistance, electrical insulation, and thermal stability compared to many traditional materials such as plywood and plastics.

4. Can G10 FR4 sheets be customized?

Absolutely! G10 FR4 sheets can be cut and shaped to meet specific project requirements, providing versatility in applications.

5. What is the cost of G10 FR4 sheets?

While they may have higher initial costs than some alternatives, their durability and low maintenance needs make them a cost-effective choice in the long run.

Conclusion

G10 FR4 sheets have established themselves as an essential material in modern construction, thanks to their unique properties and diverse applications. Their strength, insulation capabilities, and resistance to environmental factors make them invaluable in a variety of construction scenarios. As the industry continues to evolve, G10 FR4 sheets are poised to play an increasingly important role, particularly in the pursuit of sustainability and safety in building practices. Embracing G10 FR4 sheets not only enhances the quality of construction but also contributes to a safer and more resilient built environment.

More Information

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com