FR4 Tubing: Lightweight, Durable, High-Pressure Resistant—The Next-Generation Material for Electronics and Aerospace

Time of issue: 2025-09-26

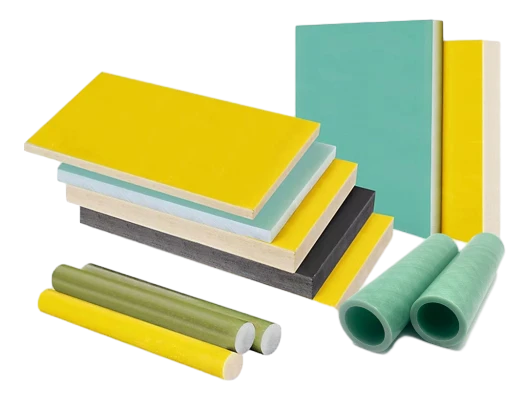

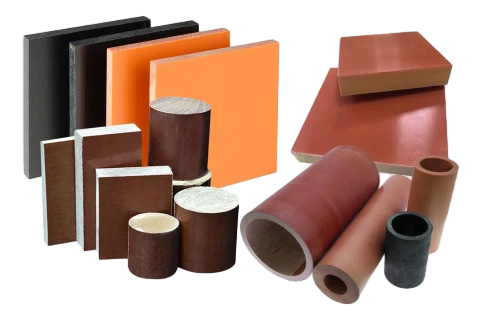

As materials science continues to advance, FR4 Tube is starting to catch the attention of multiple industries. This tubular composite, made of epoxy resin and high-strength glass fiber, has favorable performance and has won the market for its stability and versatility. FR4 Tube is becoming the "new favorite" in many industries such as electronics, energy, and aerospace due to its unique performance advantages.

Core Performance 1: Electrical and Weather Resistance

Insulation Strength: Dielectric strength greater than 20kV/mm with volume resistivity of 10¹² Ω·cm remains stable in complicated electrical, high voltage, and high power environments.

Temperature Range: Application range from -50°C to +155°C and continuous operation in high-temperature and low-temperature environments.

Flammability Rating: UL94V-0 rated with good to excellent self-extinguishing performance for additional safety.

Core Performance 2: Mechanical Structure

Strength Comparable to Steel: With a tensile strength exceeding 300MPa and a compressive strength exceeding 250MPa, it meets structural requirements.

Light Weight: Approximately 70% lighter than steel, it reduces shipping and installation costs and allows for more complex structural solutions.

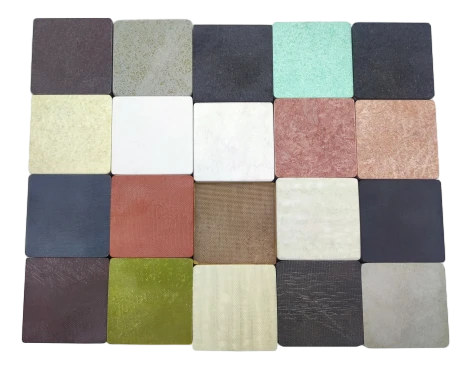

Core Performance 3: Corrosion Resistance and Simple Machining

Excellent Corrosion Resistance: Good to excellent moisture, oil, and chemical resistance extends its life expectancy dramatically.

Ease of Machining: Drilled, cut, or C.N.C. finished with no delamination or loss of surface integrity, comes with tremendous design flexibility.

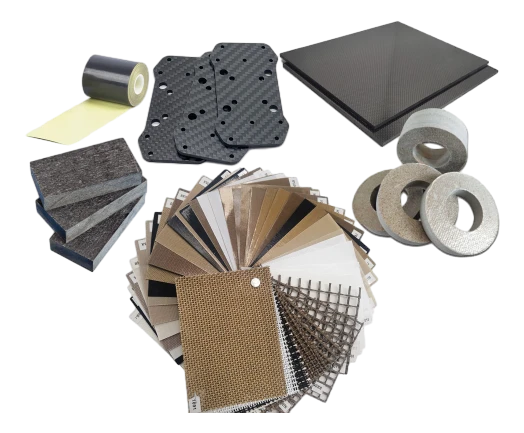

Applications: From electronics to avionics, high-performance solutions for all industries.

Electronics: Used in circuit board reinforcements and insulation bushings for transformers and inductors, increasing reliability levels.

Energy: Used in hollow insulators for high voltage cable systems and spacers for SF6 gas-insulated equipment for safe operations

Industrial and Aerospace: Used in robotic structural components, conveyor system rollers, and lightweight components for drones and satellites, achieving high-strength, lightweight designs..

Above all, the FR4 Tube is more than just a material - it is an act of industrial power for innovation and disputes in circumstances. With the combined advantages of "lightweight + high durability + low cost", it helps companies break through the performance bottleneck of traditional materials and provides more flexible solutions for innovation in high-end equipment manufacturing, new energy, and other fields.

More Information

2025-09-12

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com