735 series high temperature insulation board

It is made of high-strength glass fiber cloth and modified high-temperature resistant resin laminated composite, combined with electronic-grade environmentally friendly formula system, does not contain halogen, heavy metals and other harmful ingredients, and is cured and formed through a special process, combining high-temperature stability and environmental safety.

Category:

Key words:

high temp fiber board

high temp insulation sheet

high temperature thermal insulation sheet

-

Product Composition

It is made of high-strength glass fiber cloth and modified high-temperature resistant resin laminated composite, combined with electronic-grade environmentally friendly formula system, does not contain halogen, heavy metals and other harmful ingredients, and is cured and formed through a special process, combining high-temperature stability and environmental safety.

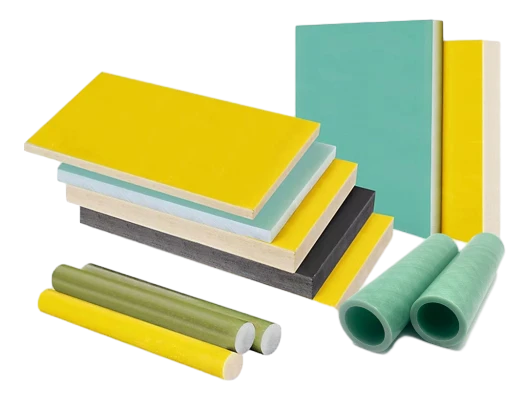

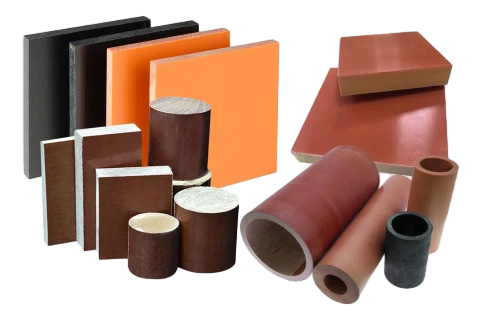

Product Specifications

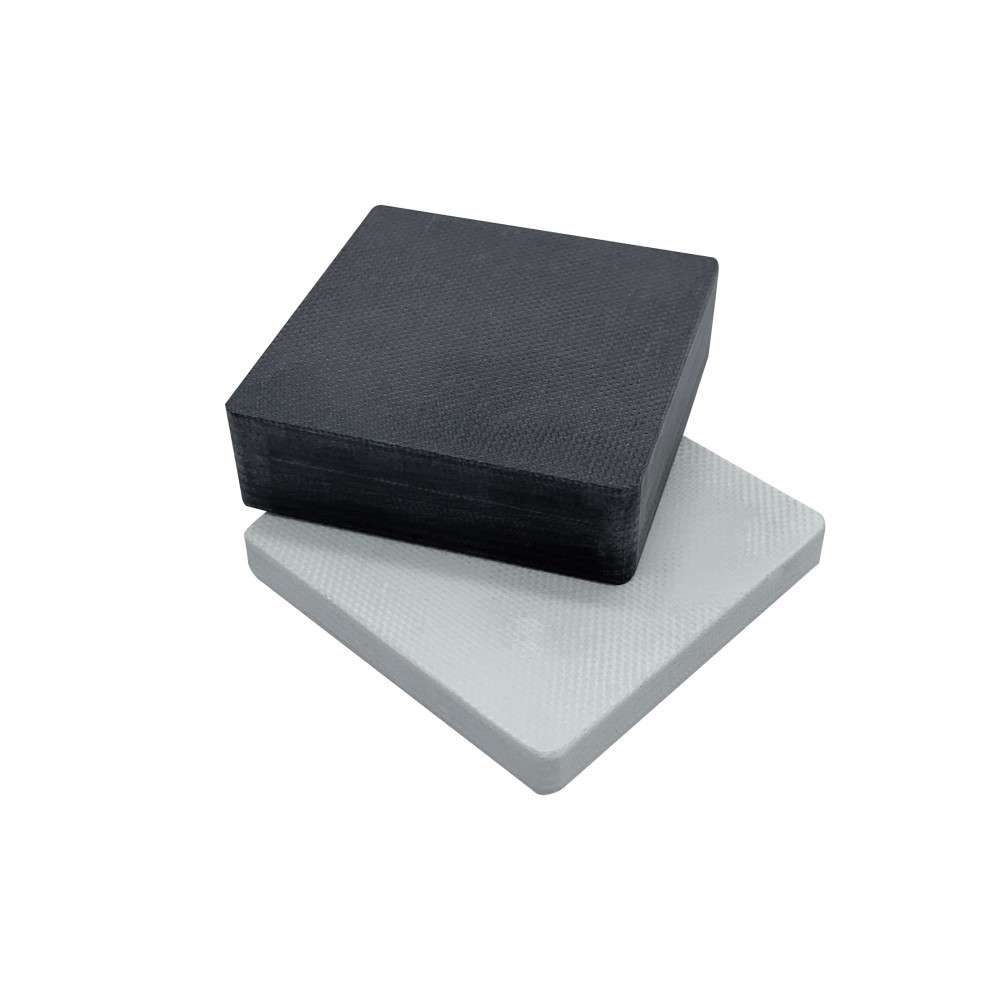

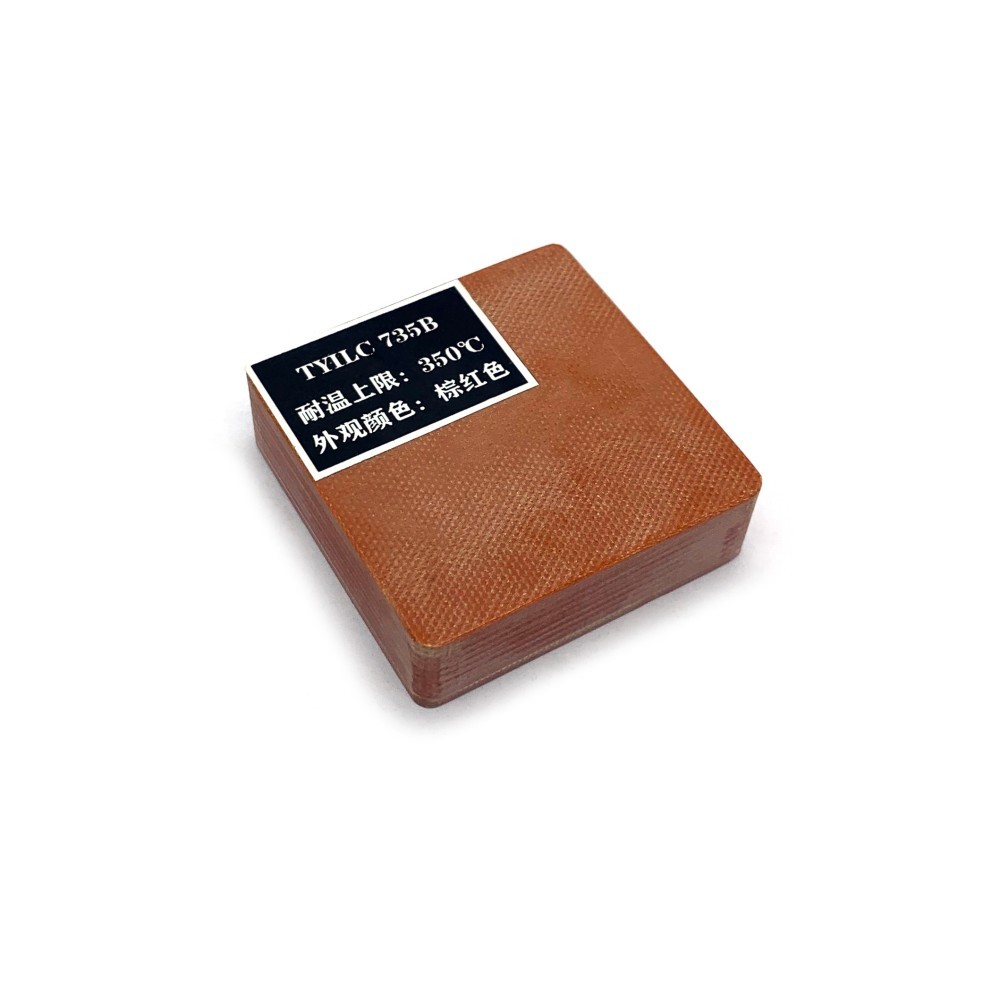

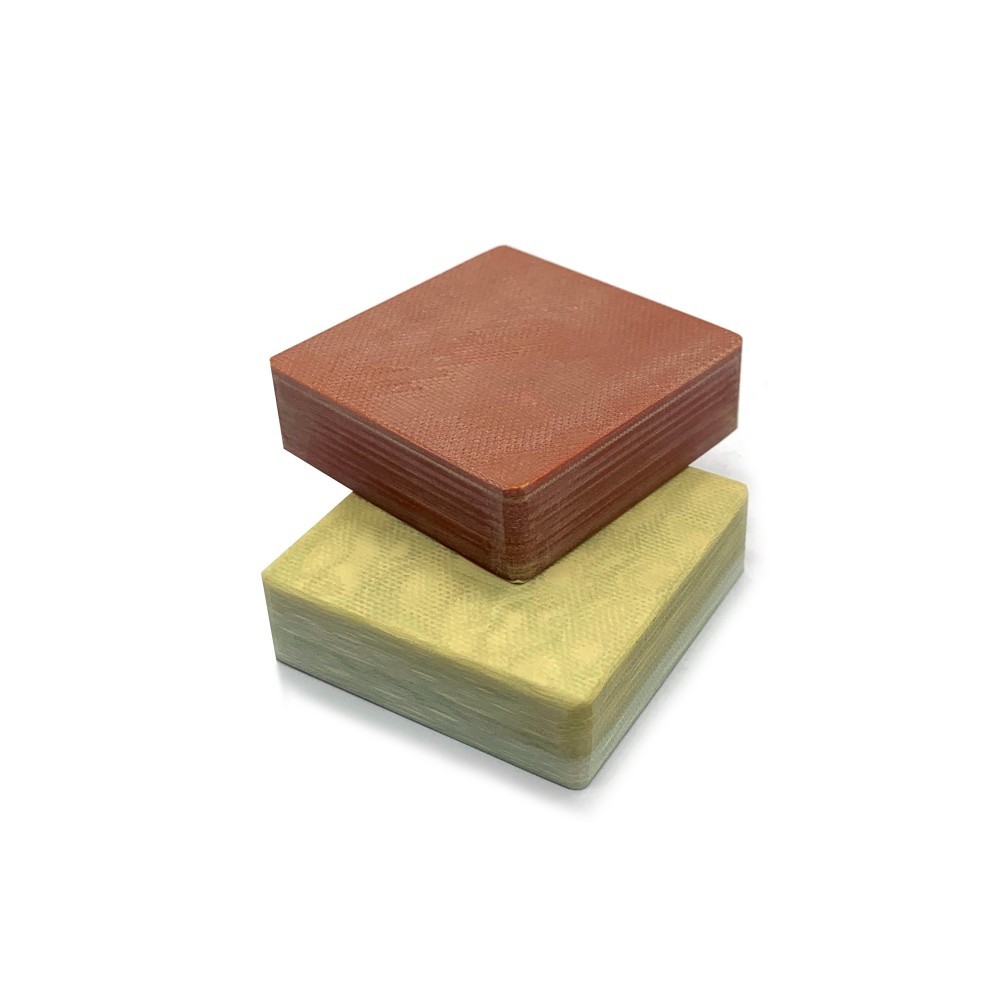

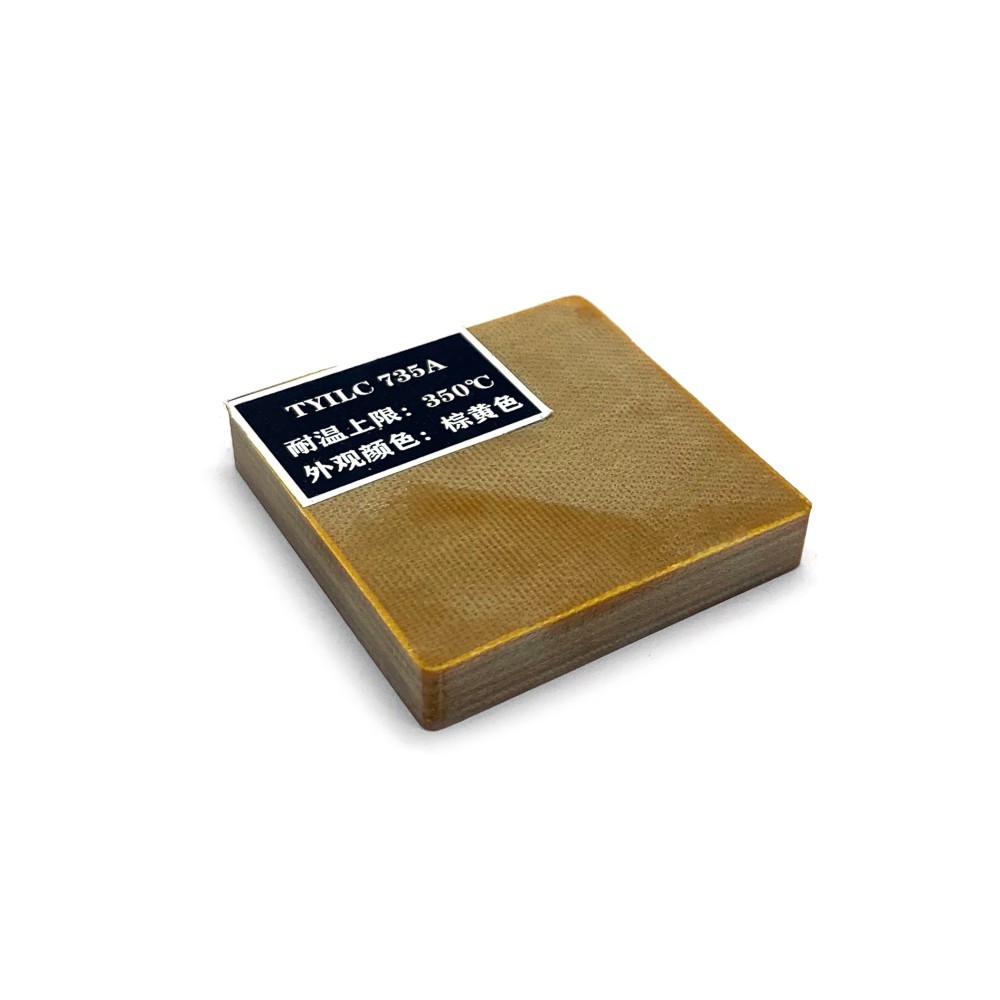

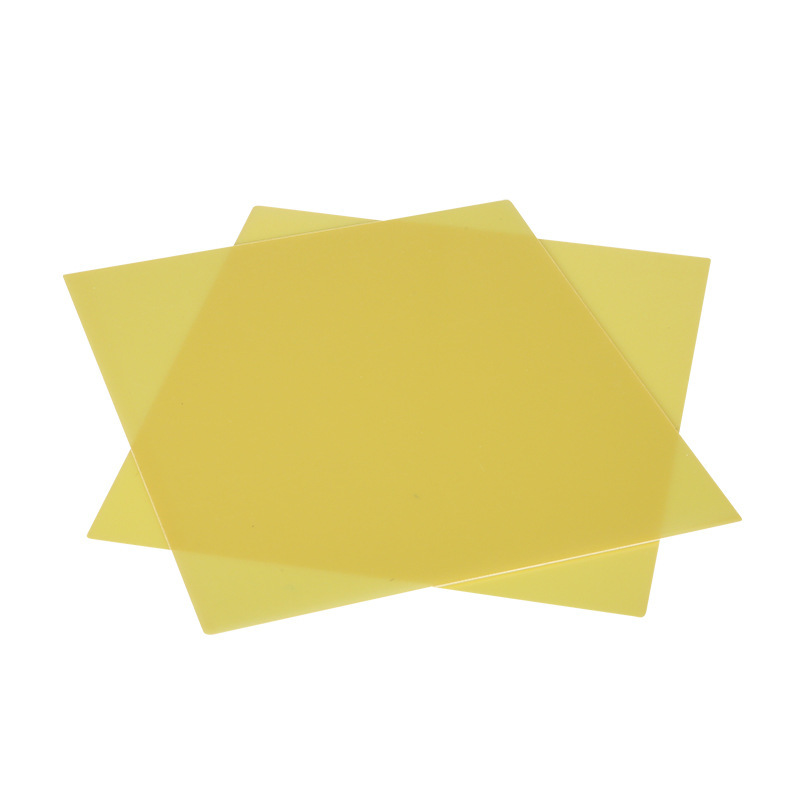

TYILC735B Color: Brown Red Size: 1220*2440mm

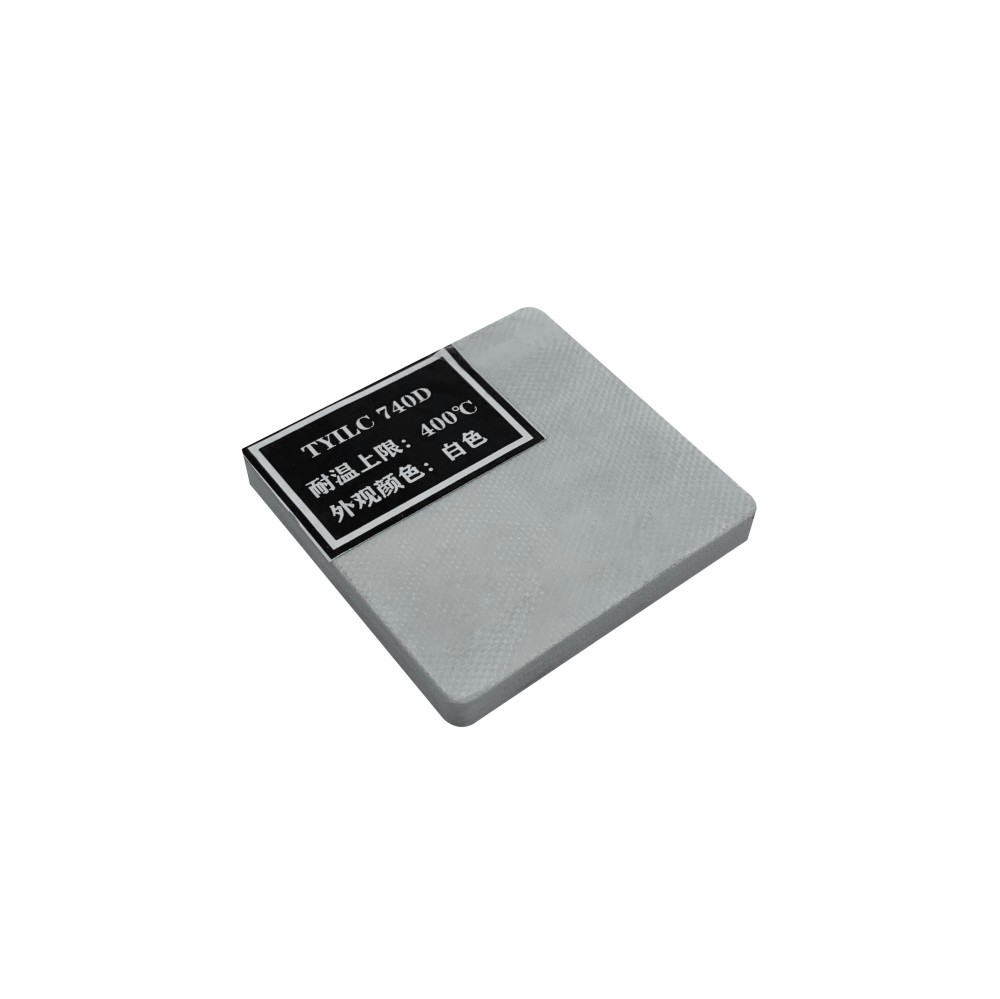

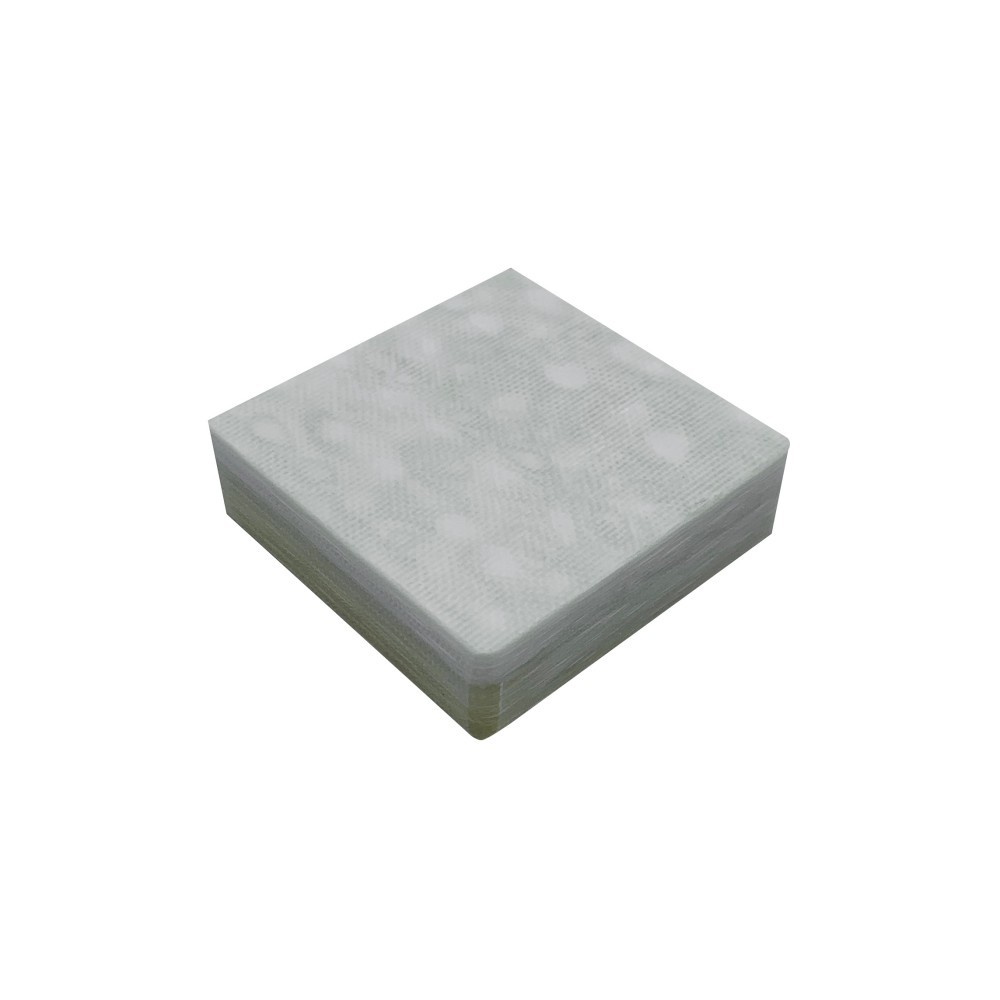

TYILG740D Color: White Size: 1220*1220mm

Performance Characteristics

Ultra-wide temperature tolerance

Normal to 400℃ continuous operation without delamination, short-term tolerance to 450℃ extreme temperature, solving the pain point of high-temperature equipment insulation.

Three-dimensional reinforced structure

Glass fiber cloth three-dimensional interweaving process + modified resin gradient penetration, compressive strength ≥ 200MPa, bending load increased by 40%.

Thermal stability breakthrough

Thermal expansion coefficient ≤ 3×10⁻⁶/℃, no cracking after 500 cycles of -40℃~400℃, ensuring the dimensional stability of precision equipment.

Functional integrated protection

Nano-level hydrophobic coating + fluorocarbon resin encapsulation, waterproof grade IPX7, oil resistance passed ASTM D471 standard test.

Long-term life guarantee

Anti-oxidation formula system, laboratory accelerated aging test (250℃×3000h) retention rate ≥ 92%, service life extended by 30%.

Safety and environmental protection certification

Compliant with ROHS 3.0, REACH 224 items of control, combustion level V-0, meet medical/aerospace environmental protection requirements.

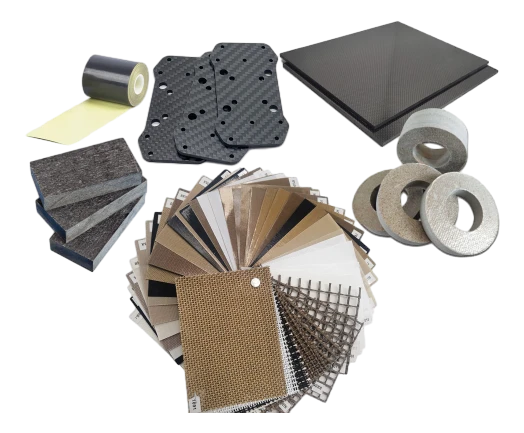

Precision machining adaptation

Support CNC engraving, laser cutting, thickness tolerance ±0.05mm, adapt to hot runner systems, semiconductor packaging and other precision scenes.Advantages

1. Import substitution, the best value for money: domestically produced innovative formula, 30%-50% lower price than similar imported materials, and full performance benchmarking with international first-line brands.

2. Extreme working condition adaptability: 400℃ long-term insulation does not fail, solving the pain point of "frequent replacement of insulation parts" in hot runner and high-temperature mold industries, and increasing equipment utilization by 20%.

3. Safety double insurance design: patented three-dimensional glass fiber reinforced structure + electronic grade flame retardant resin, UL94 V-0 certified, zero risk of compliance in aviation/medical fields.

4. Full-dimensional protection system: waterproof/oil resistant/impact resistant three-in-one, especially suitable for oily environments such as injection molding machine nozzles and packaging heat sealing heads, maintenance costs are reduced by 45%.

5. Precision process compatibility: supports ±0.05mm tolerance processing, meeting the micron-level assembly requirements of semiconductor packaging equipment and optical molds.

6. Green supply chain certification: complies with 12 international environmental protection directives such as RoHS and REACH, helping enterprises to quickly pass ISO14001 system audits.

7. Cross-industry solutions: Single products cover eight major fields including aerospace (heat shield), medical devices (sterilization equipment), new energy (battery modules), etc., reducing the cost of managing multiple suppliers.Application Fields

1. High-end rubber and plastic industry: Injection molding machine nozzle insulation, hot runner system protection, rubber vulcanizer template insulation, improve molding accuracy, and save more than 30% energy.

2. Precision packaging and printing: Heat sealing knife insulation, die-cutting machine platen protection, hot stamping equipment temperature control, solve the problem of material deformation caused by thermal radiation.

3. Aerospace field: Rocket engine nozzle insulation, satellite component vacuum thermal test protection, aircraft engine turbine blade transportation fixture.

4. New energy and automation: Lithium battery module thermal management, photovoltaic laminator insulation, industrial robot high temperature operation protection, withstand harsh working conditions.

5. Hot processing equipment: Flat vulcanizer insulation board, mold heating plate support, hot press insulation layer, ensure ±2℃ process temperature stability.

6. Shipbuilding and marine engineering: Marine diesel engine exhaust pipe insulation, submarine pipeline welding insulation, offshore platform equipment fire barrier, corrosion resistance and salt spray resistance.

7. Semiconductor and optics: wafer baking furnace lining, optical lens hot bending mold, laser equipment beam path insulation to meet clean room application requirements.

FAQ

Is there a discount for purchase?

Is there a discount for purchase?

Yes! We offer preferential prices based on the order quantity. Please contact our business staff for details on the specific discount. We will provide you with the most favorable plan based on your order quantity!

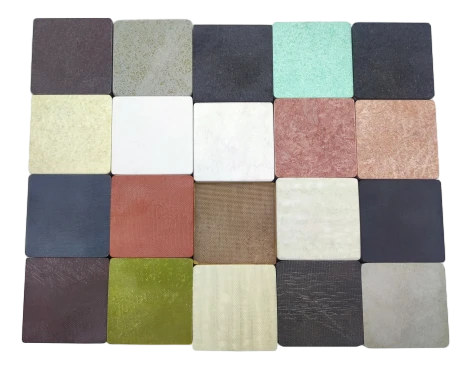

What if there is a color difference between the actual product and the picture?

What if there is a color difference between the actual product and the picture?

All our products are taken from real objects. However, due to factors such as shooting environment, light, and differences in parameter settings of different display devices, there may be slight color differences between the pictures and the actual products you receive. Please refer to the actual product received for the product color.

How is the product packaged?

How is the product packaged?

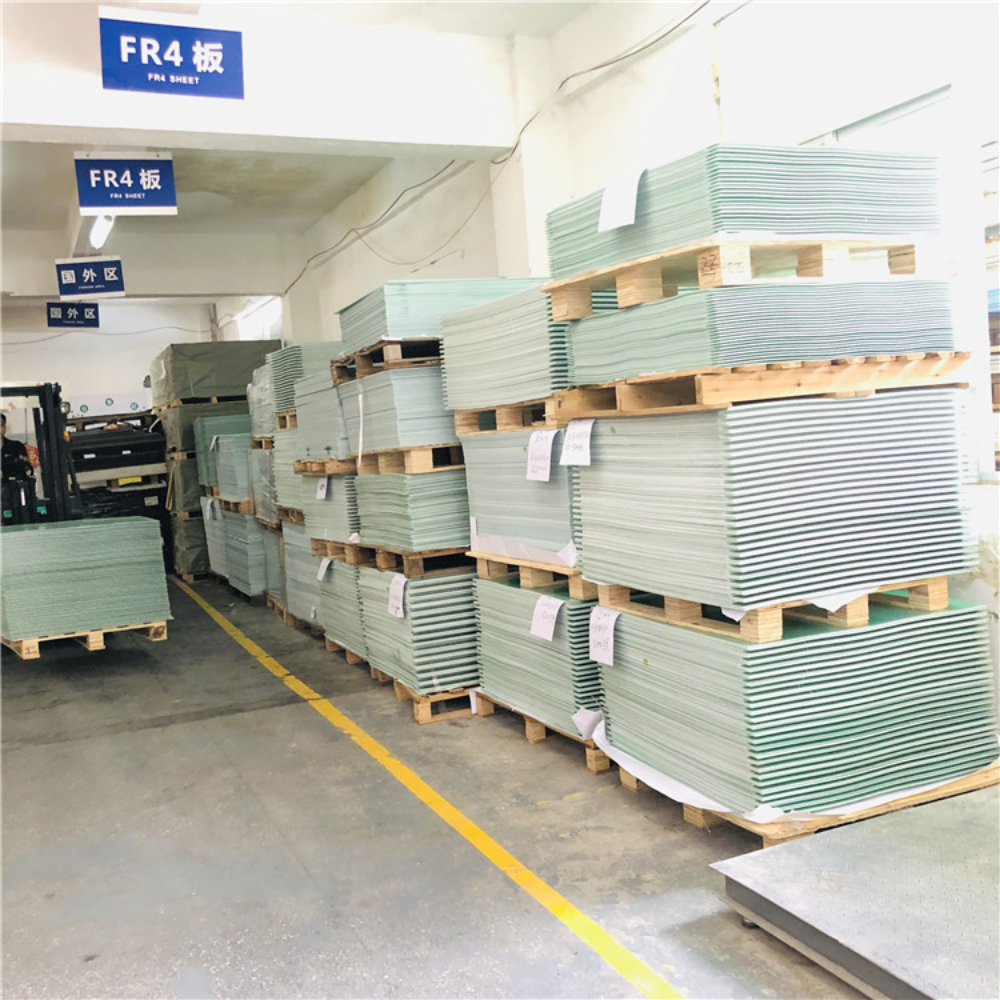

Conventional packaging is pallets for plates, wooden boxes for bars, cartons for processed parts or according to customer requirements.

How long does it usually take to deliver?

How long does it usually take to deliver?

Generally, our standard delivery cycle is 7 to 30 days after receiving the deposit to confirm the order. Please note that the exact time may vary depending on the specific product model you ordered, the complexity of the process, and the quantity ordered. For customized products or large-volume orders, we will provide a more precise delivery schedule when confirming the order.

How does your company ensure product quality?

How does your company ensure product quality?

Product quality is our primary concern. We have established a complete quality control system that runs through the entire process of raw material procurement, production process and final product inspection. We adopt strict standards and ensure that every product delivered to customers meets requirements and standards through methods such as ISO9001 certification and multiple quality inspection processes.

Can you cut or engrave it into the shape we want?

Can you cut or engrave it into the shape we want?

Yes. We have large cutting machines and engraving machines that can be customized.

Certificate Honor

Corporate Atlas

Related Products

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com