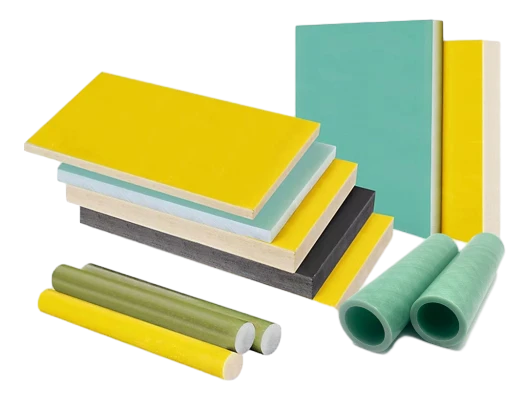

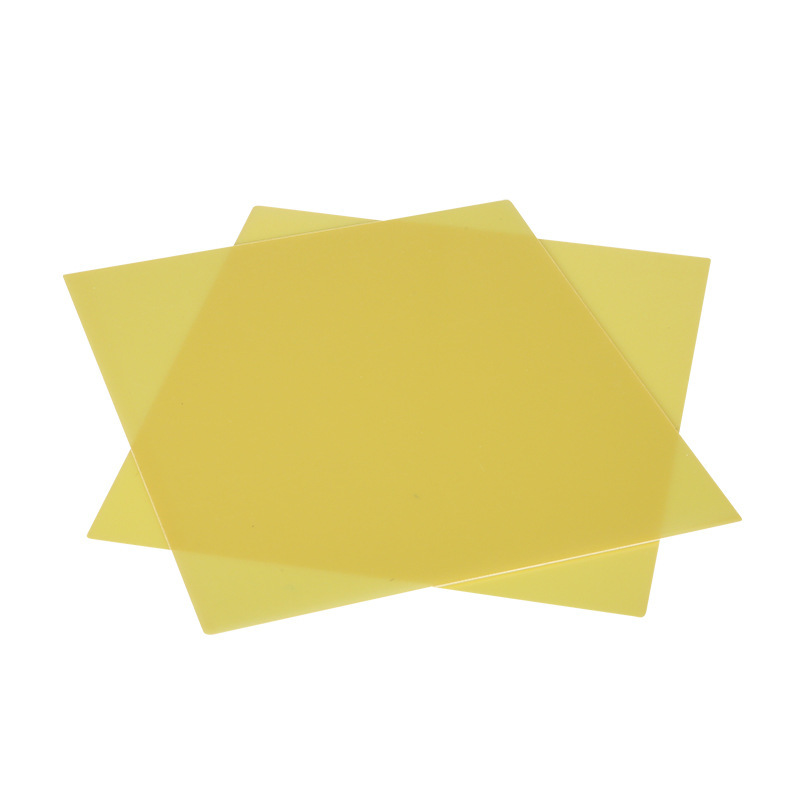

3240 Epoxy Fiberglass Laminated Sheet

Made of alkali-free glass fiber cloth impregnated with epoxy resin and then hot-pressed and cured (conforms to EPGC 201 type in IEC60893 standard).

Category:

Key words:

3240 Epoxy Sheet

3240 Insulate Sheet

Epoxy Fiberglass 3240 Sheet

-

Product Composition

Made of alkali-free glass fiber cloth impregnated with epoxy resin and then hot-pressed and cured (conforms to EPGC 201 type in IEC60893 standard).

Product Specifications

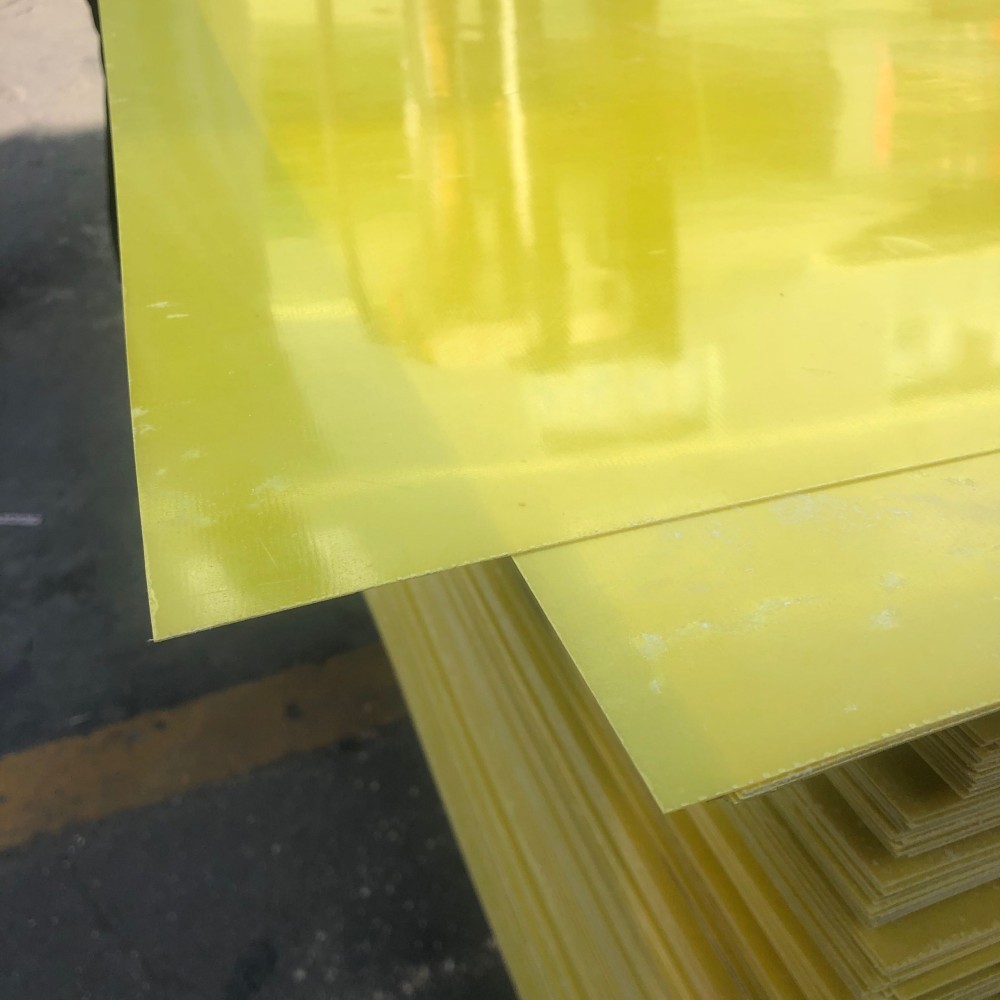

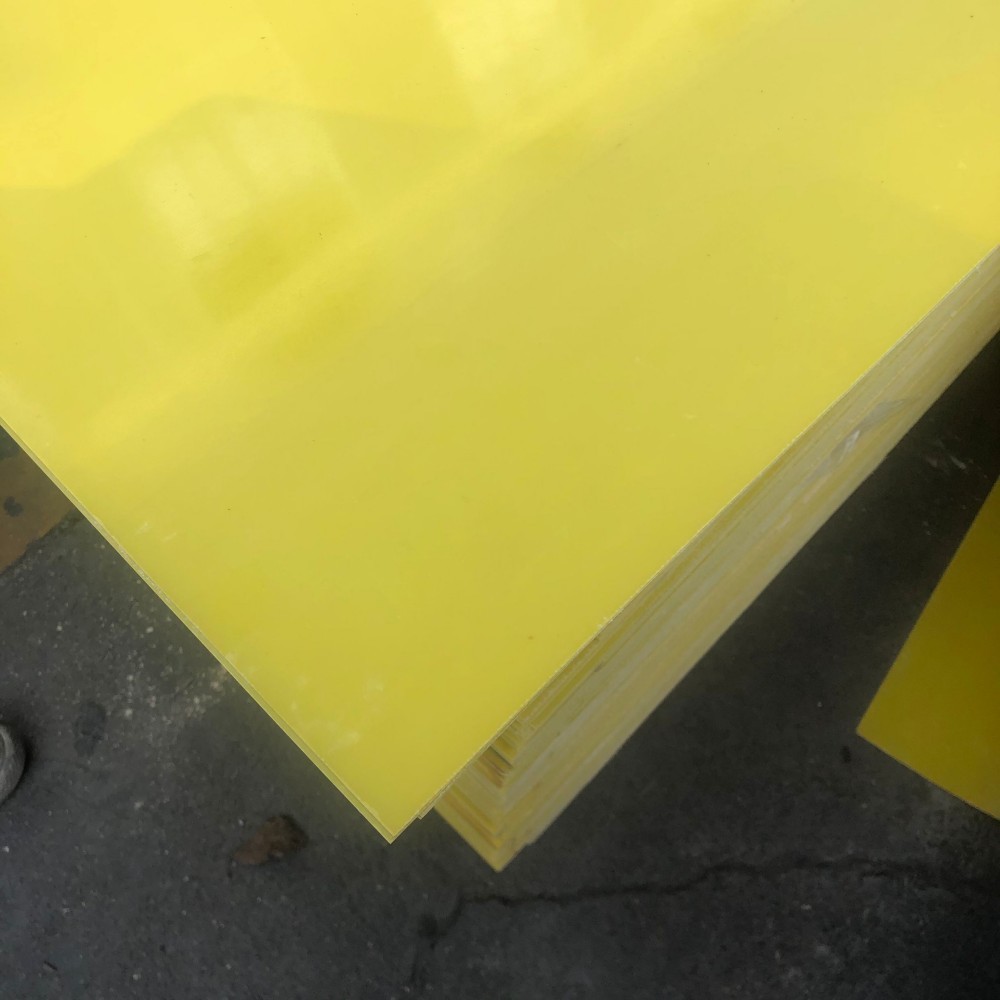

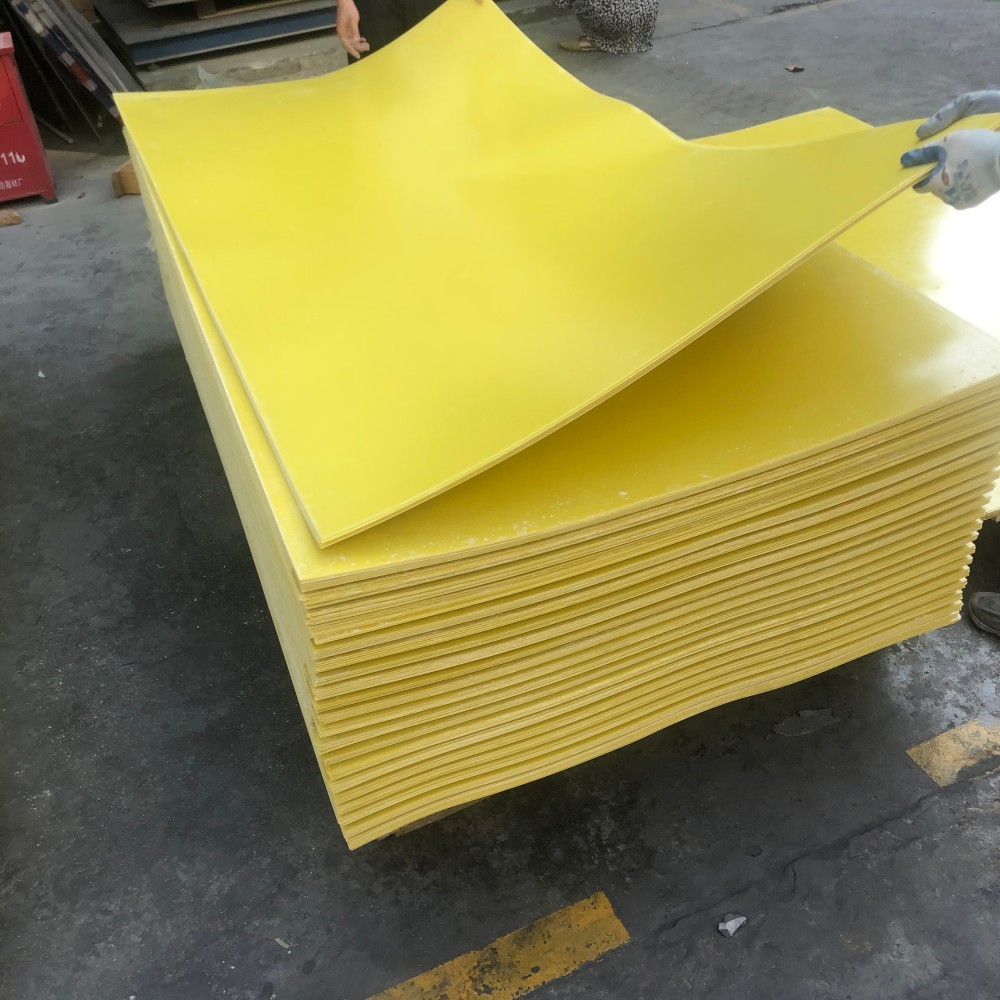

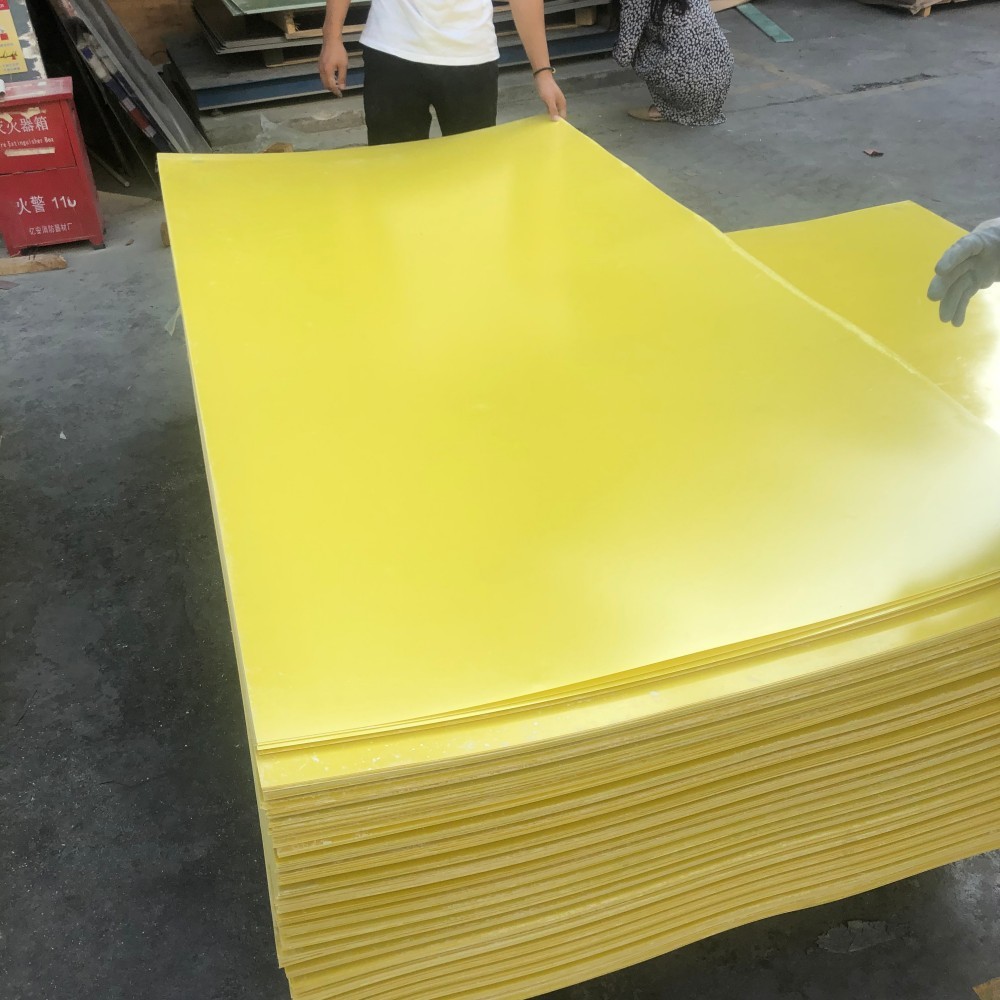

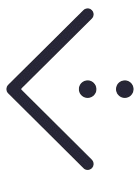

Regular size: 1000*2000mm, 1220*2440mm

Regular color: yellow

Regular thickness: 0.5-200mmPerformance Characteristics

High Strength: The epoxy fiberglass plate exhibits uniform and high strength, suitable for various complex structures.

Corrosion Resistance: Due to its unique chemical composition, the plate is highly resistant to acids, alkalis, and other chemicals.

Waterproof: The epoxy fiberglass plate possesses excellent waterproofing properties, making it suitable for use in damp environments.

Electrical Insulation: The plate has a high insulation rating, commonly used as an insulating material in electrical and electronic industries.

Stable Electrical Properties: Its electrical performance remains stable at high temperatures, ensuring the smooth operation of equipment.

Heat and Moisture Resistance: The epoxy fiberglass plate maintains good performance under high temperatures and humidity.

Good Processability: The plate can be processed into various complex shapes through various techniques such as compression molding, extrusion, and manual lamination, meeting the needs of various parts, equipment, and devices.Advantages

High insulation reliability: suitable for high-voltage electrical equipment, stable insulation performance, excellent arc resistance.

Outstanding mechanical strength: strong impact resistance and deformation resistance, suitable for structural support parts and wear-resistant parts.

Environmental adaptability: high temperature resistance, humidity resistance, corrosion resistance, can be used for a long time under harsh working conditions.

Cost-effectiveness: compared with special engineering plastics (such as PEEK), it is cheaper and more cost-effective.Application Fields

1. Electrical insulation field

Motors and transformers: used as motor slot wedges, transformer insulation pads, coil skeletons, etc.

High-voltage equipment: circuit breaker insulation plates, switch cabinet supports.

2. Mechanical structure field

Fixtures: insulation pads and mold substrates in precision machining (due to low deformation rate).

Wear-resistant parts: gears, bearing bushings (scenarios that require wear resistance and insulation).

3. Electronic equipment

Heat dissipation substrate: insulation heat dissipation substrate for high-power electronic components (such as IGBT modules).

PCB auxiliary materials: test fixtures, drilling pads (taking advantage of their high flatness and high temperature resistance).

4. Special industries

Railway transportation: high-speed rail/subway insulation components (such as pantograph insulation support).

New energy: wind power converter insulation structural parts, photovoltaic inverter bracket.

FAQ

Is there a discount for purchase?

Is there a discount for purchase?

Yes! We offer preferential prices based on the order quantity. Please contact our business staff for details on the specific discount. We will provide you with the most favorable plan based on your order quantity!

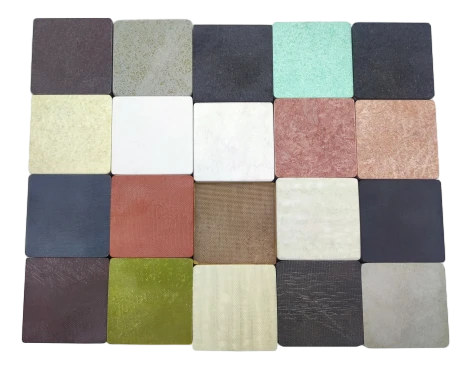

What if there is a color difference between the actual product and the picture?

What if there is a color difference between the actual product and the picture?

All our products are taken from real objects. However, due to factors such as shooting environment, light, and differences in parameter settings of different display devices, there may be slight color differences between the pictures and the actual products you receive. Please refer to the actual product received for the product color.

How is the product packaged?

How is the product packaged?

Conventional packaging is pallets for plates, wooden boxes for bars, cartons for processed parts or according to customer requirements.

How long does it usually take to deliver?

How long does it usually take to deliver?

Generally, our standard delivery cycle is 7 to 30 days after receiving the deposit to confirm the order. Please note that the exact time may vary depending on the specific product model you ordered, the complexity of the process, and the quantity ordered. For customized products or large-volume orders, we will provide a more precise delivery schedule when confirming the order.

How does your company ensure product quality?

How does your company ensure product quality?

Product quality is our primary concern. We have established a complete quality control system that runs through the entire process of raw material procurement, production process and final product inspection. We adopt strict standards and ensure that every product delivered to customers meets requirements and standards through methods such as ISO9001 certification and multiple quality inspection processes.

Can you cut or engrave it into the shape we want?

Can you cut or engrave it into the shape we want?

Yes. We have large cutting machines and engraving machines that can be customized.

Certificate Honor

Corporate Atlas

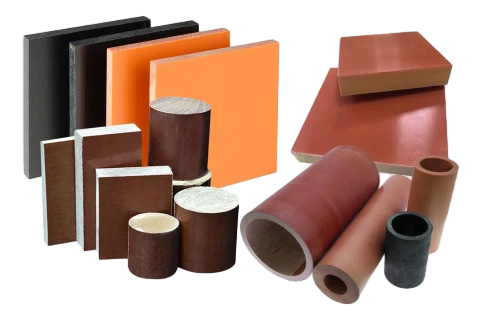

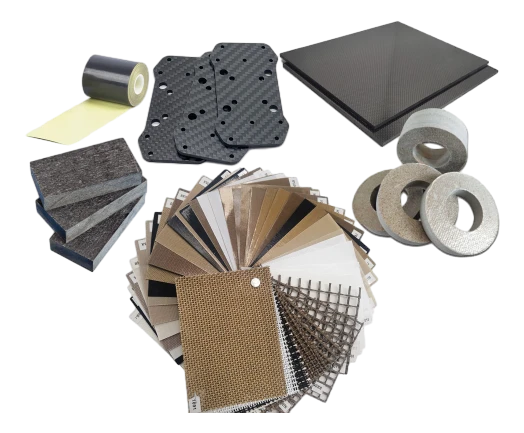

Related Products

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com