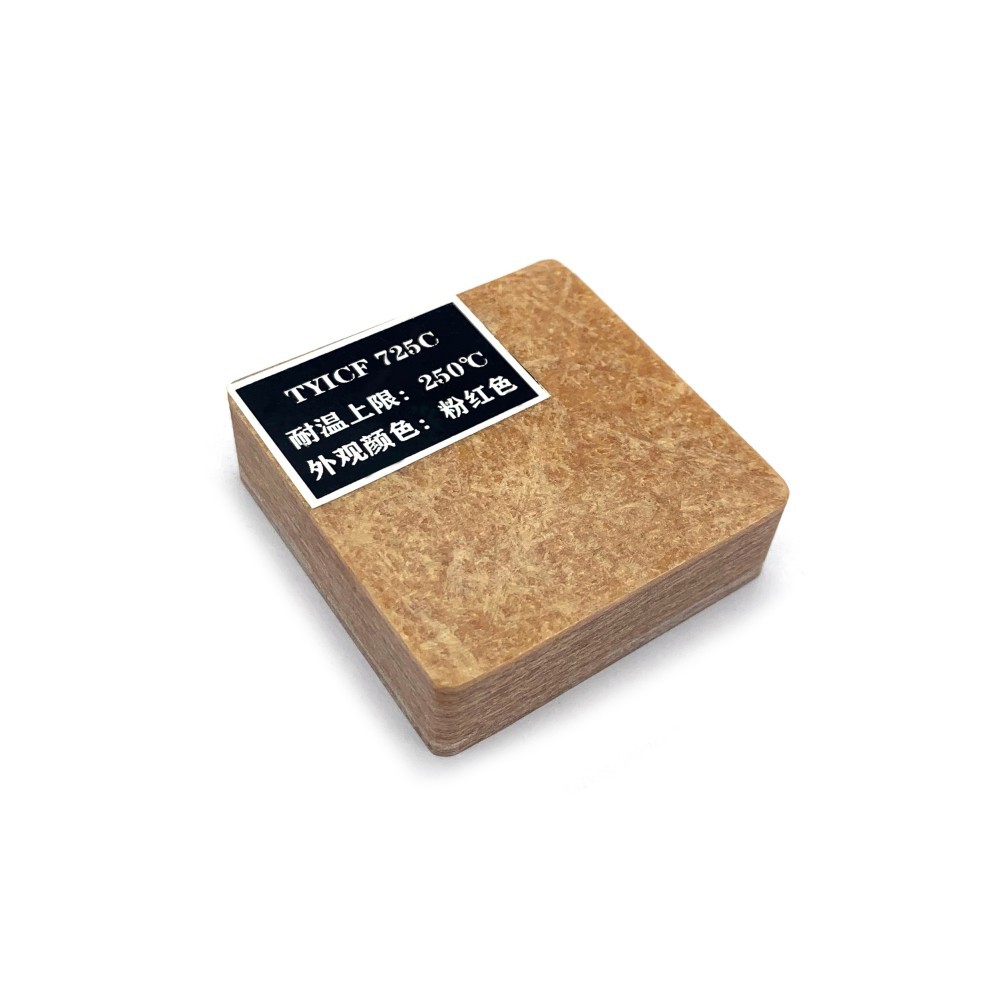

725 series high temperature insulation board

With high-silica glass fiber mat + modified phenolic/polyimide resin as the core, it is composited by vacuum hot pressing. It is asbestos-free, halogen-free and flame-retardant, complies with RoHS/REACH environmental protection standards, and is suitable for 250℃ high-temperature industrial insulation scenarios.

Category:

Key words:

high temperature insulation board

high temperature insulation sheet

high heat insulation board

-

Product Composition

With high-silica glass fiber mat + modified phenolic/polyimide resin as the core, it is composited by vacuum hot pressing. It is asbestos-free, halogen-free and flame-retardant, complies with RoHS/REACH environmental protection standards, and is suitable for 250℃ high-temperature industrial insulation scenarios.

Product Specifications

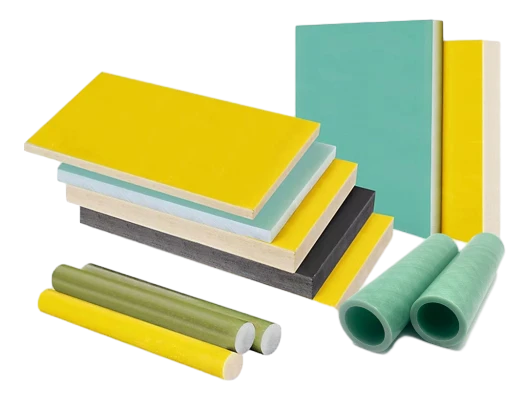

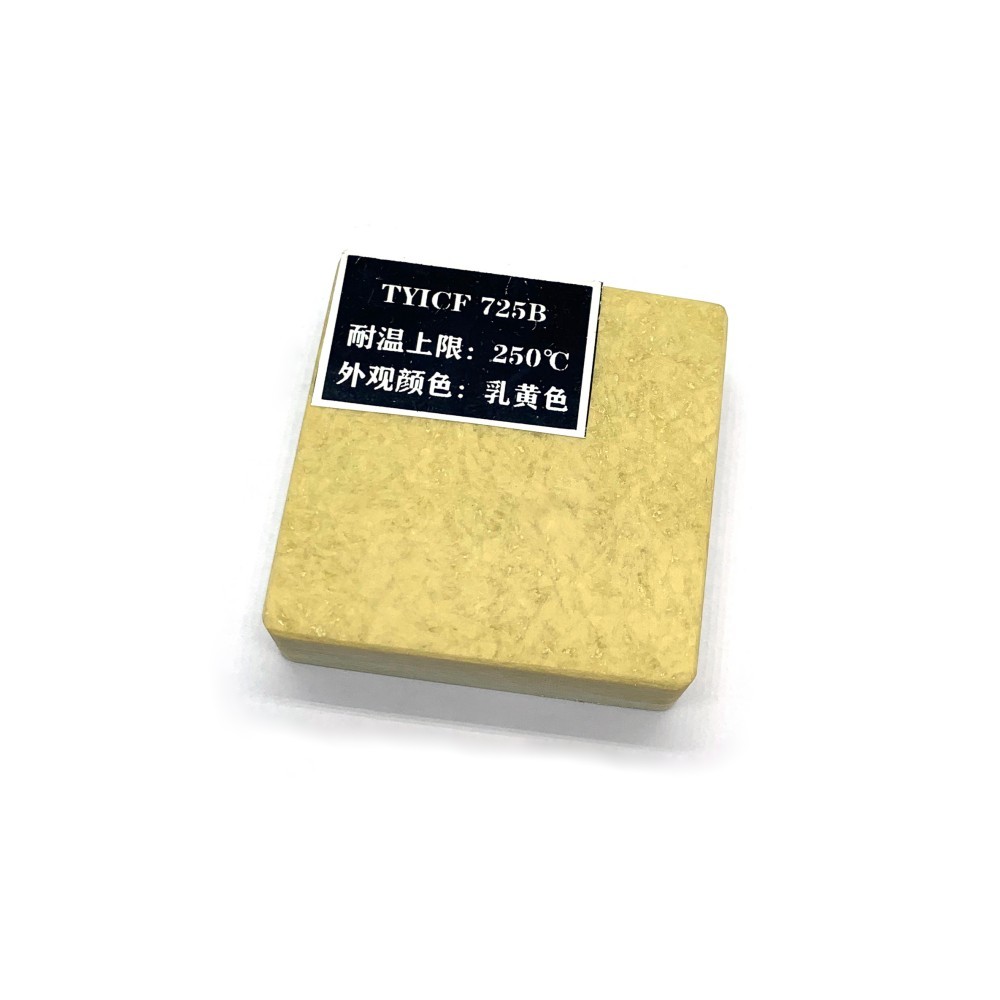

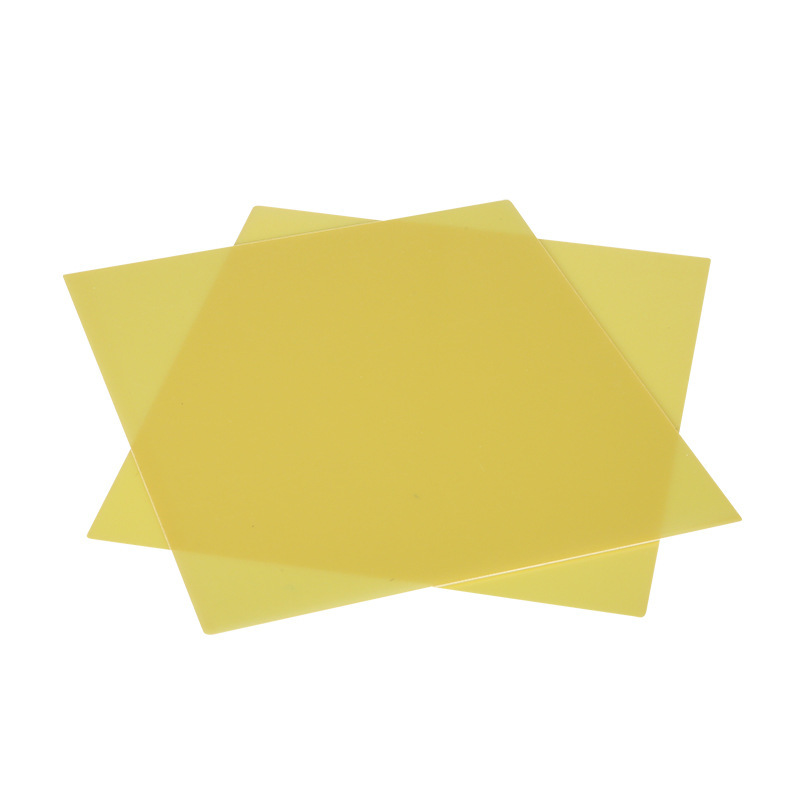

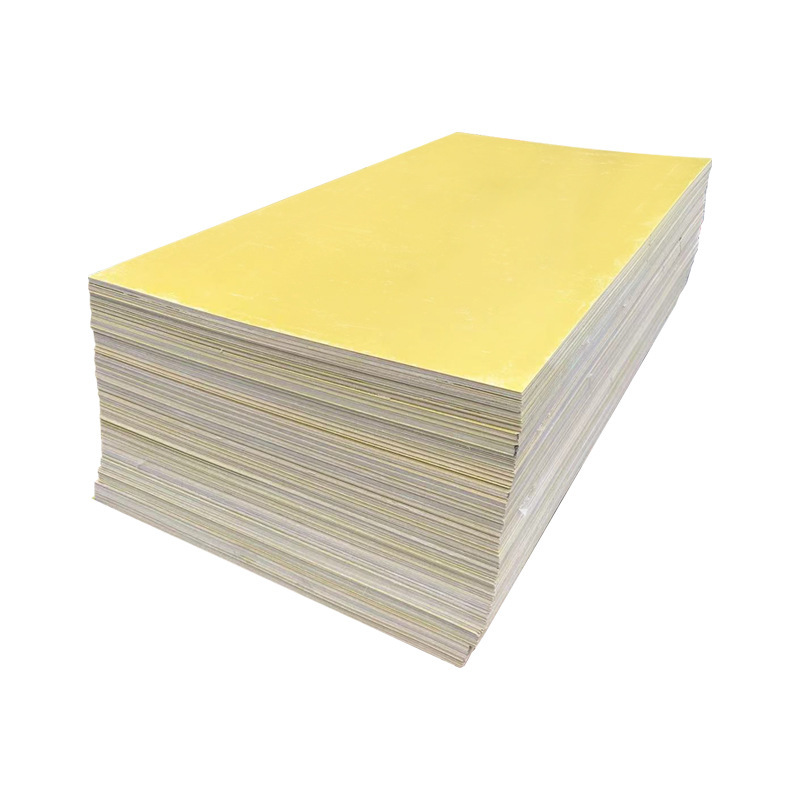

TYICF725B Color: Creamy yellow Size: 1220*2440mm

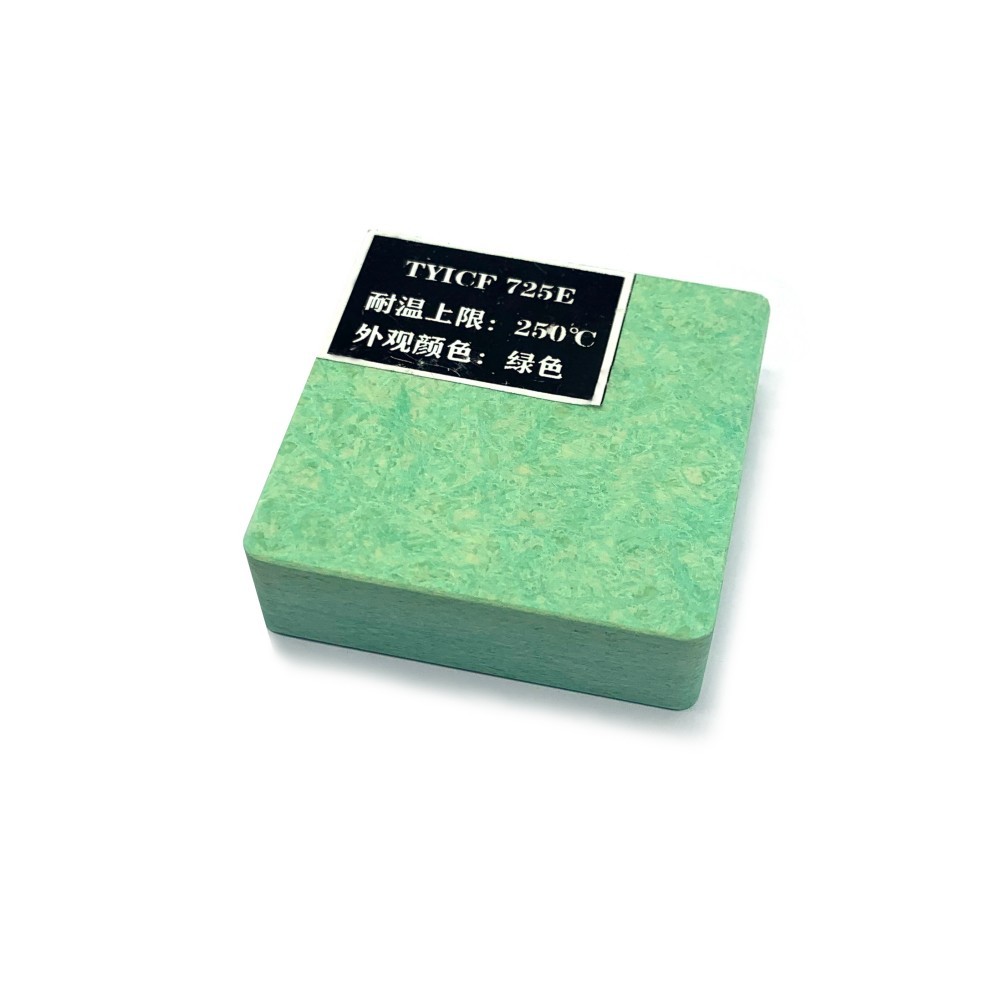

TYICF725E Color: Green Size: 1220*2440mm

Performance Characteristics

1. Ultra-high temperature resistance: The long-term use temperature range of polyimide is -200 to 300°C, and polyetheretherketone can be used for a long time at 250°C, and the instantaneous temperature resistance can reach above 300°C.

2. Excellent stability: The resin molecular chain structure is stable, not easy to decompose at high temperature, and maintains lasting physical and chemical properties.

3. Good adhesion: It is firmly combined with glass fiber felt to form a dense composite structure and improve the overall strength.

4. Thermal stability: Through nano-ceramic modification technology, the thickness expansion rate at high temperature (250°C/24h) is less than 0.3%, ensuring the stability of equipment accuracy.

5. Precision machining adaptation: It adopts a three-dimensional reinforced fiber structure to support complex processing such as CNC milling, laser cutting, and drilling, and the minimum machining hole diameter can reach φ2mm.

6. Surface flatness: Special resin coating technology, surface roughness Ra <0.8μm, directly meets the needs of high-precision mold assembly.

7. Oil resistance: Passed the ASTM D471 standard test, and was immersed in hydraulic oil and thermal oil for 72 hours without deformation.

Advantages

1. Heat-resistant dual temperature range: basic model 230℃, upgraded model limit 260℃, stable performance without degradation.

2. High-precision processing: supports CNC/laser precision processing (φ2mm hole), surface Ra<0.8μm treatment-free.

3. Flexible customization: provide special-shaped structural designs such as wave/L-type/ultra-thin (2mm).

4. Environmental protection dual certification: zero asbestos, compliant with RoHS/REACH, optional food grade (FDA).

5. Low carbon with statement: with carbon footprint certification and EPD environmental protection statement.

6. Hydrophobic and oil-resistant: water-repellent (contact angle>110°), oil-resistant and chemical-resistant.

7. Super-efficient thermal insulation: ultra-low thermal conductivity (0.032 W/mK), reducing heat loss by 18-22%, ensuring uniform temperature field.

8. Low maintenance cost: Modular design reduces maintenance cost by 50%+ and shortens downtime.Application Fields

1. Tire vulcanization: shorten the vulcanization cycle and improve tire uniformity.

2. Injection molding/hot pressing: ensure stable mold temperature and improve molding accuracy.

3. New energy batteries: block thermal runaway and meet high safety standards.

4. Packaging and printing: optimize the temperature distribution of drying equipment and improve paper quality.

5. Hot runner system: precise temperature control to prevent cold materials and extend mold life

FAQ

Is there a discount for purchase?

Is there a discount for purchase?

Yes! We offer preferential prices based on the order quantity. Please contact our business staff for details on the specific discount. We will provide you with the most favorable plan based on your order quantity!

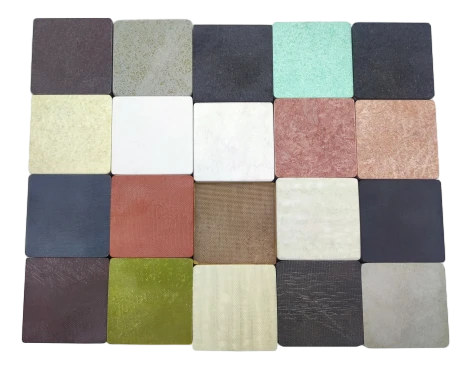

What if there is a color difference between the actual product and the picture?

What if there is a color difference between the actual product and the picture?

All our products are taken from real objects. However, due to factors such as shooting environment, light, and differences in parameter settings of different display devices, there may be slight color differences between the pictures and the actual products you receive. Please refer to the actual product received for the product color.

How is the product packaged?

How is the product packaged?

Conventional packaging is pallets for plates, wooden boxes for bars, cartons for processed parts or according to customer requirements.

How long does it usually take to deliver?

How long does it usually take to deliver?

Generally, our standard delivery cycle is 7 to 30 days after receiving the deposit to confirm the order. Please note that the exact time may vary depending on the specific product model you ordered, the complexity of the process, and the quantity ordered. For customized products or large-volume orders, we will provide a more precise delivery schedule when confirming the order.

How does your company ensure product quality?

How does your company ensure product quality?

Product quality is our primary concern. We have established a complete quality control system that runs through the entire process of raw material procurement, production process and final product inspection. We adopt strict standards and ensure that every product delivered to customers meets requirements and standards through methods such as ISO9001 certification and multiple quality inspection processes.

Can you cut or engrave it into the shape we want?

Can you cut or engrave it into the shape we want?

Yes. We have large cutting machines and engraving machines that can be customized.

Certificate Honor

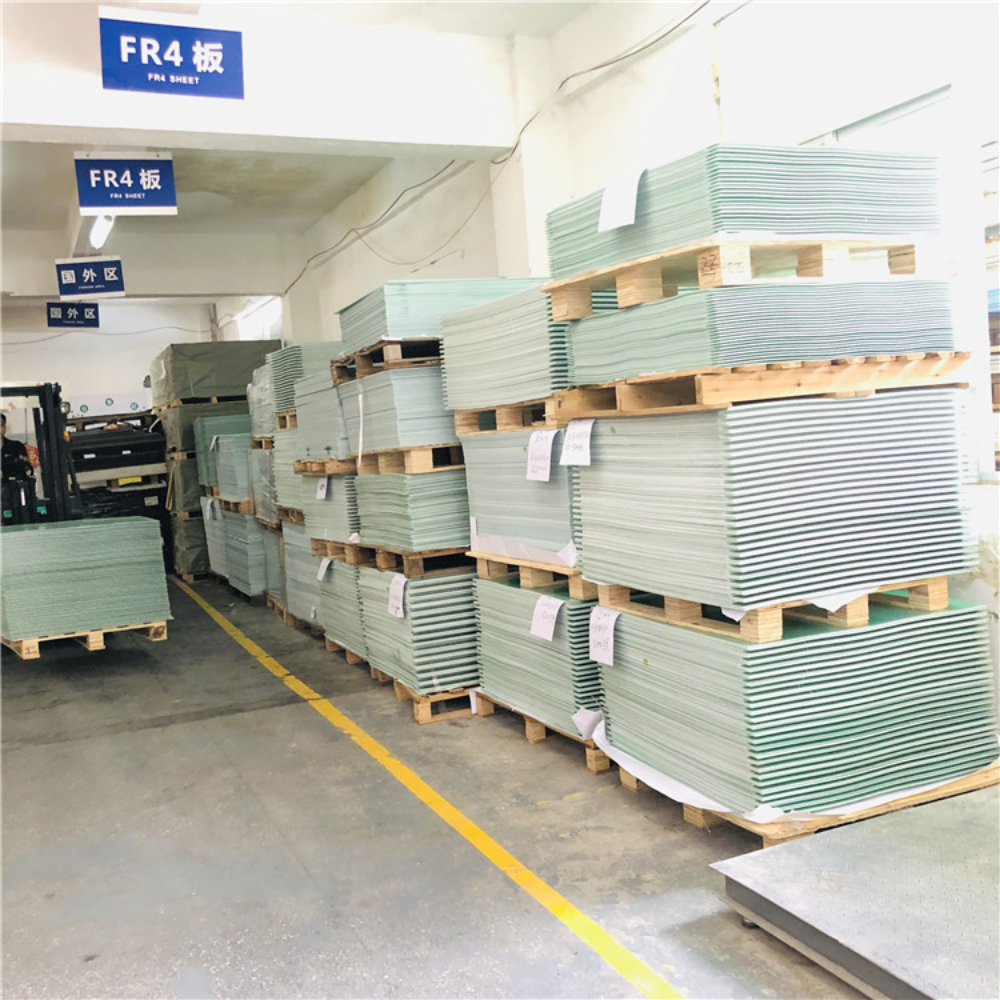

Corporate Atlas

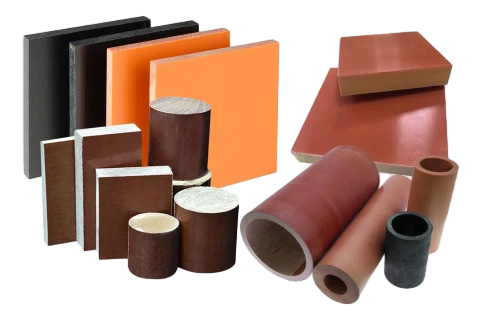

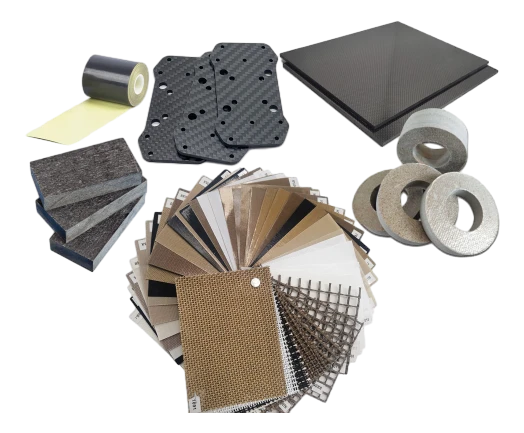

Related Products

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com