Antistatic Bakelite Sheet

Phenolic Laminated Bakelite Sheet is made from high-quality bleached wood pulp paper and cotton pulp paper as reinforcements, combined with high-purity, fully synthetic petrochemical raw materials reacting to form phenolic resin as the resin binder. Among them, phenolic resin is a hard and brittle thermosetting plastic raw material that is formed by thoroughly mixing and heating a certain proportion of sawdust powder, light calcium powder, and other additives with the phenolic resin.

Category:

Key words:

-

Product Composition

Phenolic Laminated Bakelite Sheet is made from high-quality bleached wood pulp paper and cotton pulp paper as reinforcements, combined with high-purity, fully synthetic petrochemical raw materials reacting to form phenolic resin as the resin binder. Among them, phenolic resin is a hard and brittle thermosetting plastic raw material that is formed by thoroughly mixing and heating a certain proportion of sawdust powder, light calcium powder, and other additives with the phenolic resin.

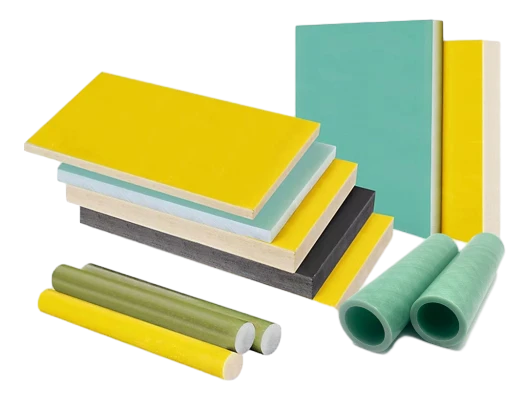

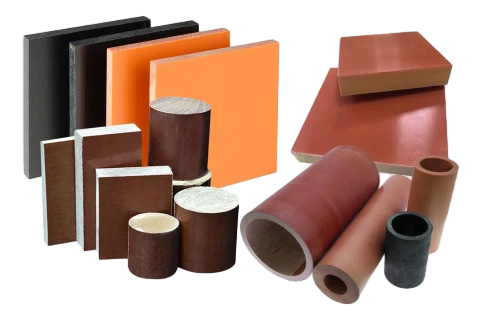

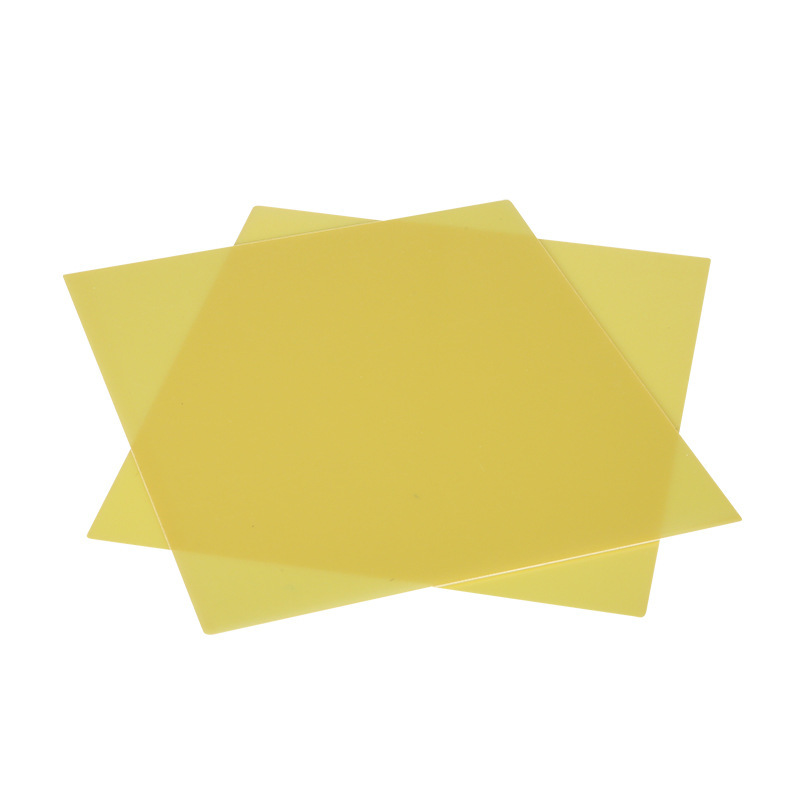

Product Specifications

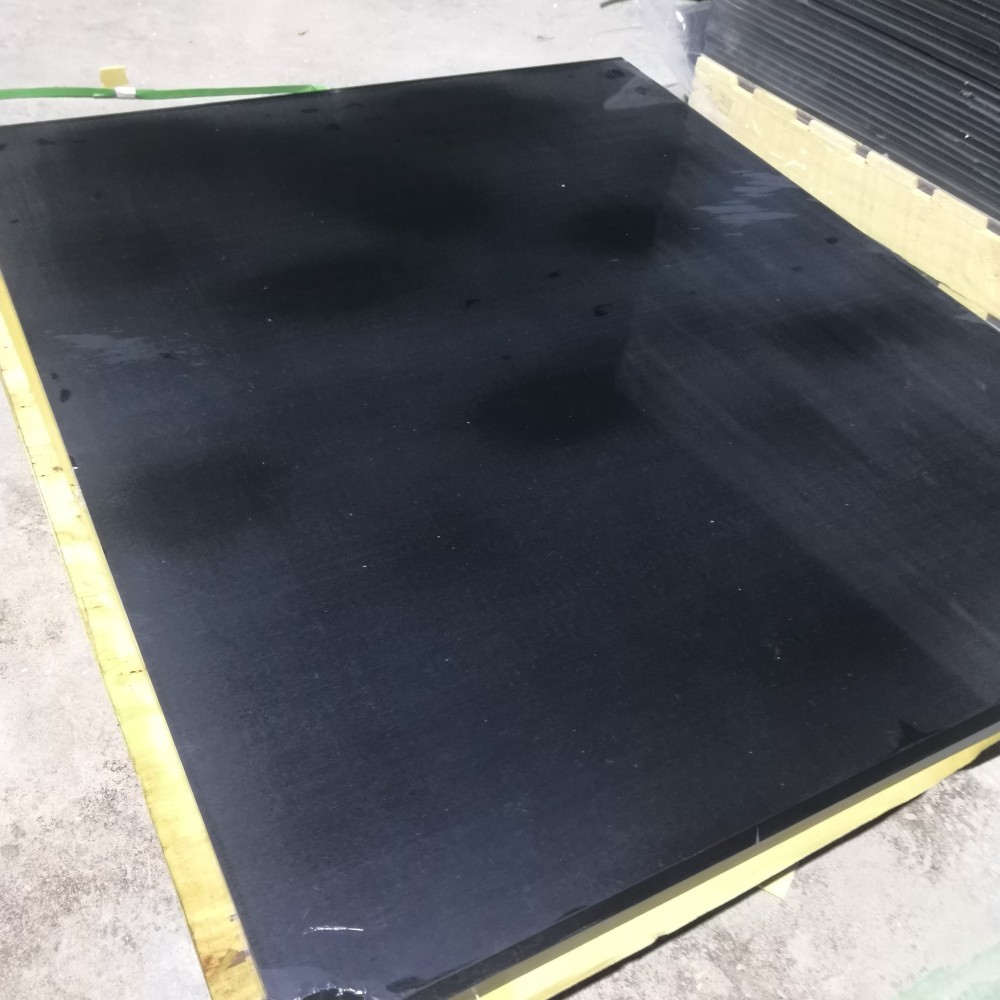

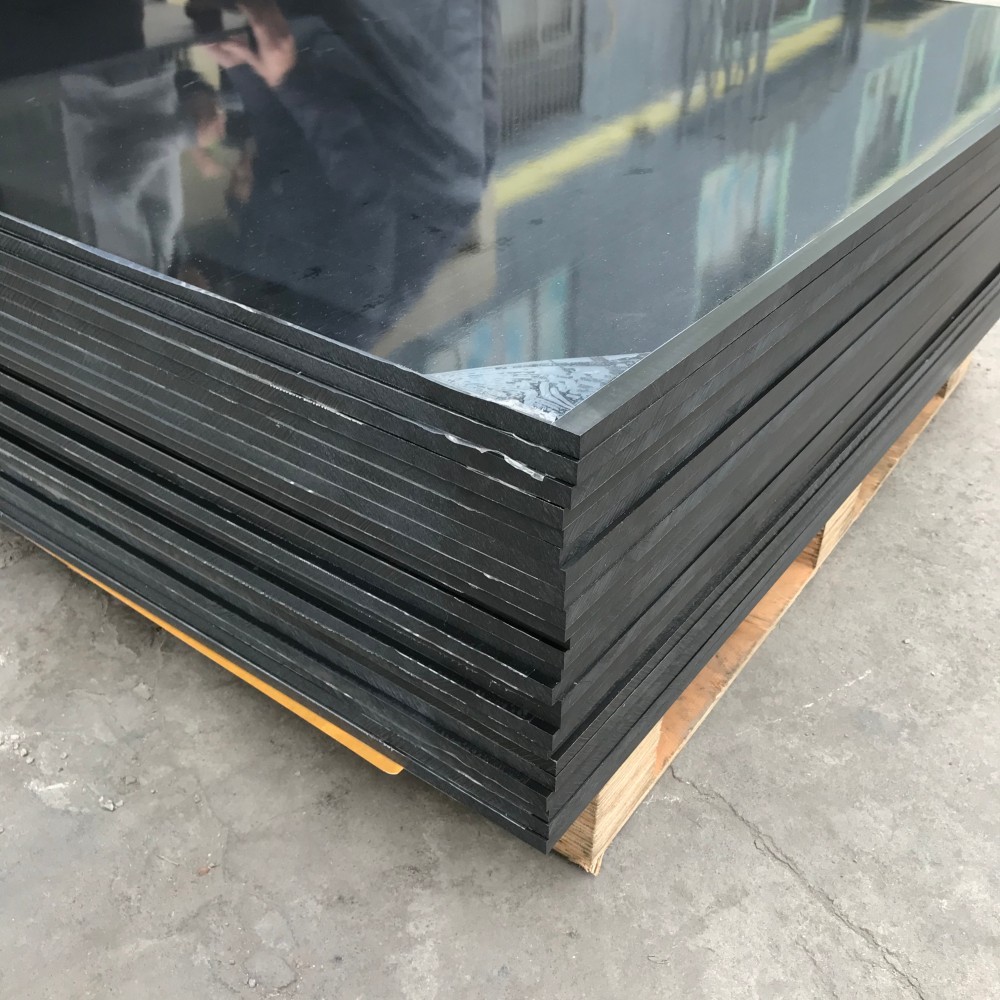

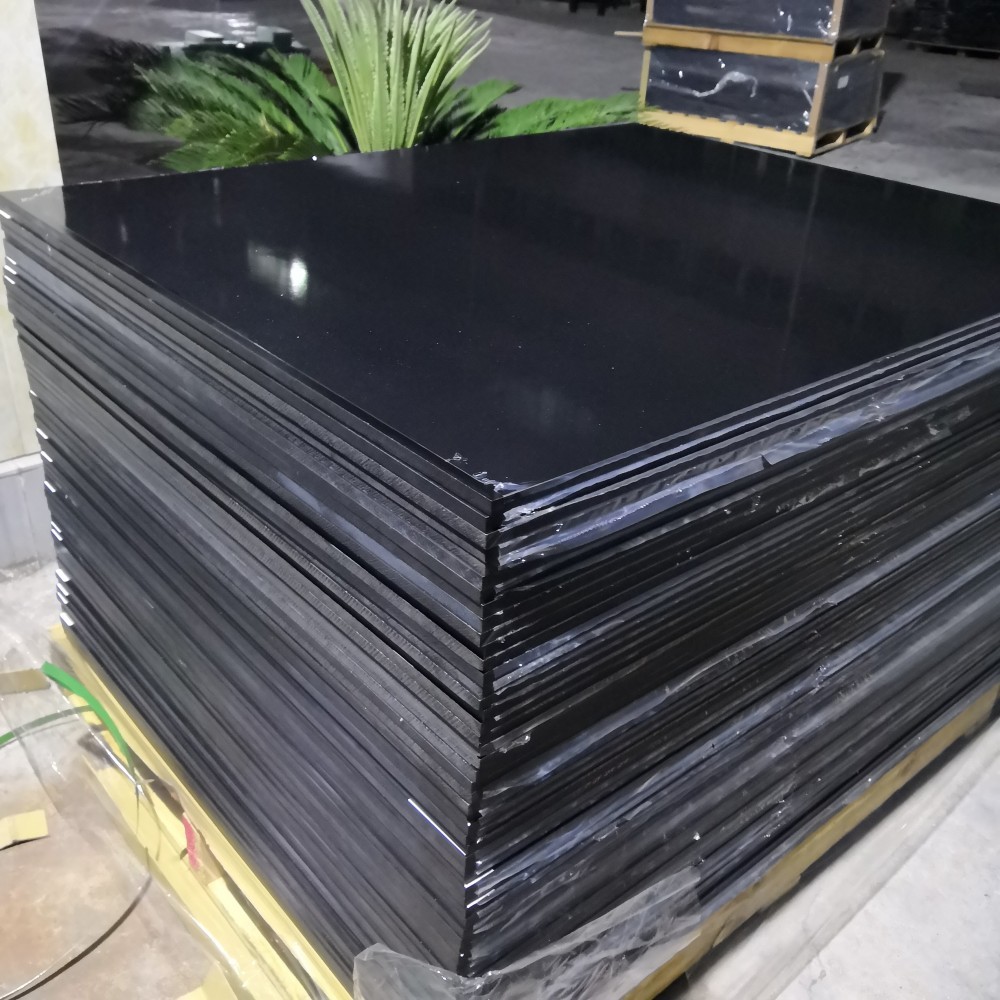

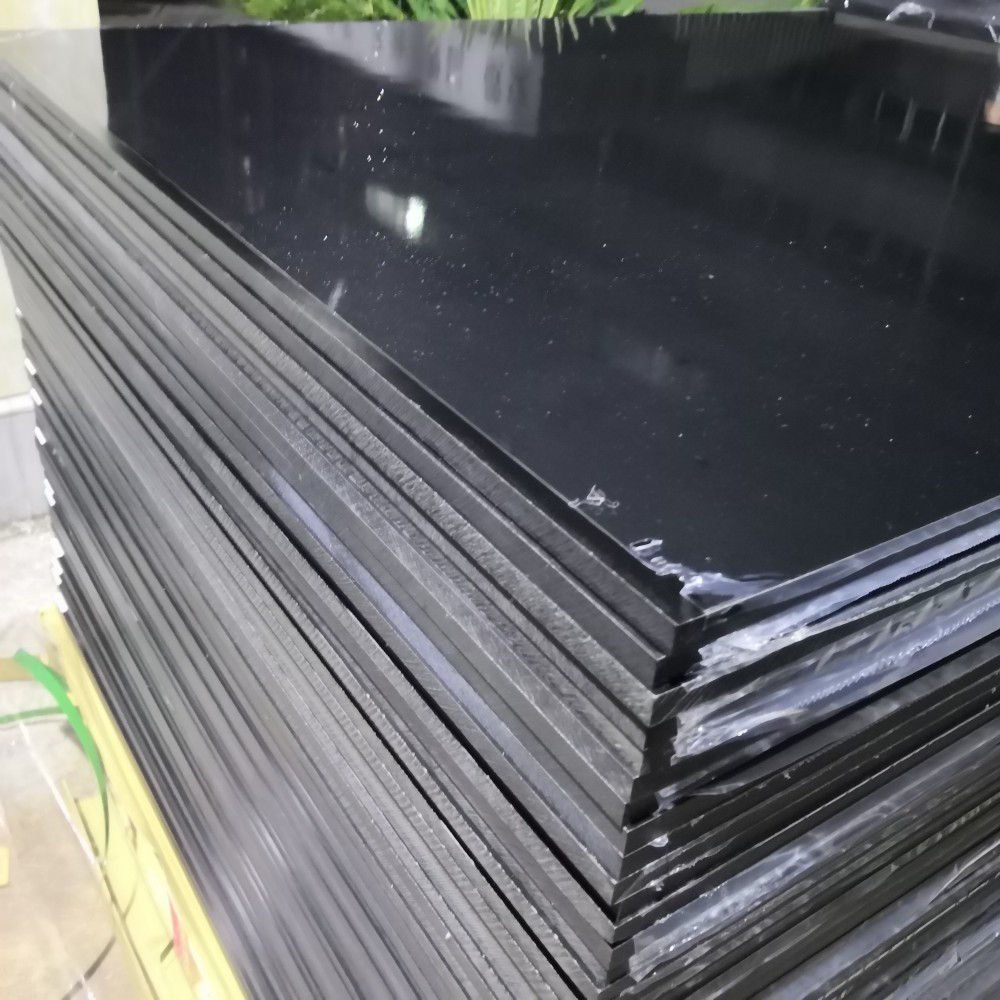

Size: 1000*2000mm, 1220*2440mm

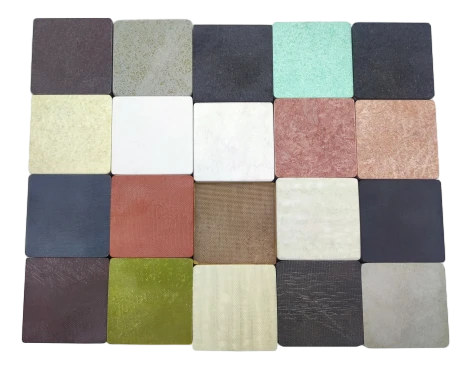

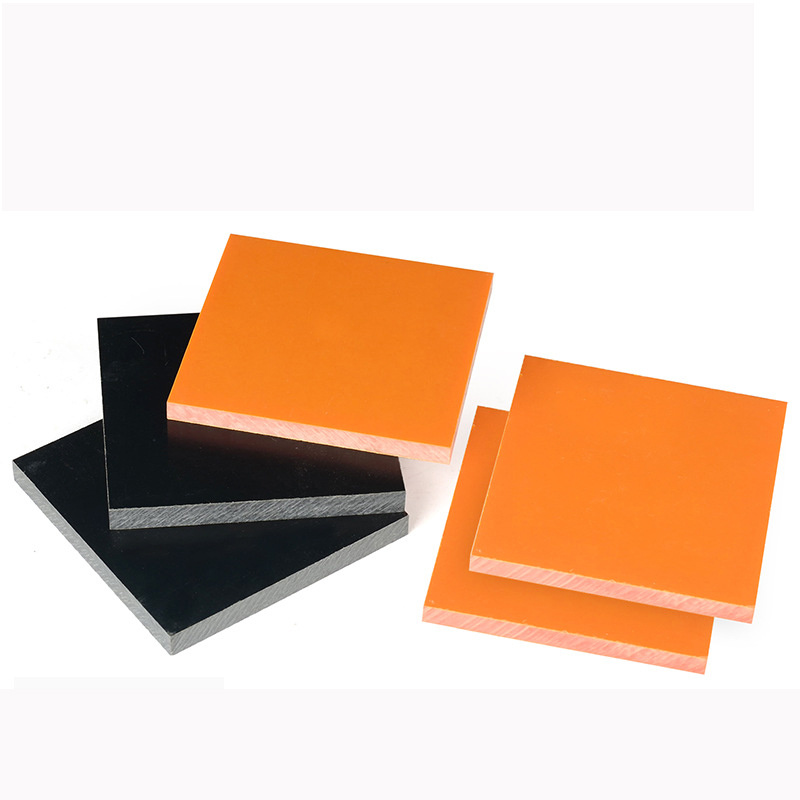

Color: red, black

Thickness: 3-100mmPerformance Characteristics

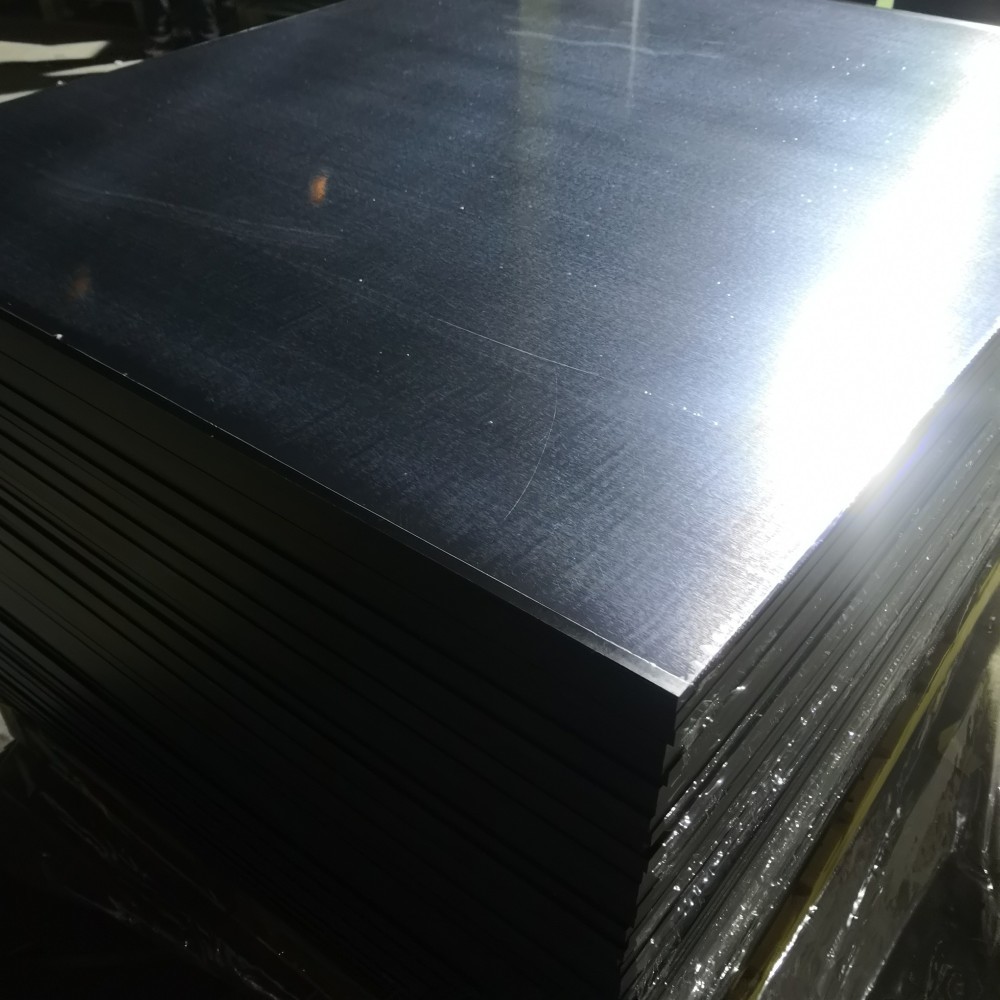

High mechanical strength, wear resistance and impact resistance.

Excellent electrical insulation performance, arc resistance.

Heat resistance, chemical corrosion resistance (weak acid, alkali, oil resistance).

Processability: easy to cut, drill, mill, suitable for making parts with complex shapes.Advantages

High cost performance: The cost is lower than epoxy resin board, suitable for large-scale industrial applications.

Strong durability: wear-resistant and aging-resistant, suitable for mechanical parts used for a long time and at high frequency.

Reliable insulation: widely used in insulating structural parts of medium and low voltage electrical equipment.

Environmental adaptability: moisture-resistant and oil-resistant, can work stably under harsh working conditions.Application Fields

Electrical field

Insulation parts: switch cabinet insulation board, circuit breaker bracket, terminal base.

Electrical accessories: meter box, socket panel, relay base.

Mechanical field

Fixtures: machine bed plate, mold base (such as stamping mold, injection mold).

Wear-resistant parts: gears, bearing seats, guide rail linings (low friction scenarios).

Daily industry

Handles and grips: tool handles (soldering iron, pliers), equipment operating levers.

Identification signs: corrosion-resistant machine nameplates and signs.

Special applications

Corrosion-resistant equipment: chemical equipment linings, oil pump seals.

Model making: mechanical models, DIY handmade parts (easy to process).

FAQ

Is there a discount for purchase?

Is there a discount for purchase?

Yes! We offer preferential prices based on the order quantity. Please contact our business staff for details on the specific discount. We will provide you with the most favorable plan based on your order quantity!

What if there is a color difference between the actual product and the picture?

What if there is a color difference between the actual product and the picture?

All our products are taken from real objects. However, due to factors such as shooting environment, light, and differences in parameter settings of different display devices, there may be slight color differences between the pictures and the actual products you receive. Please refer to the actual product received for the product color.

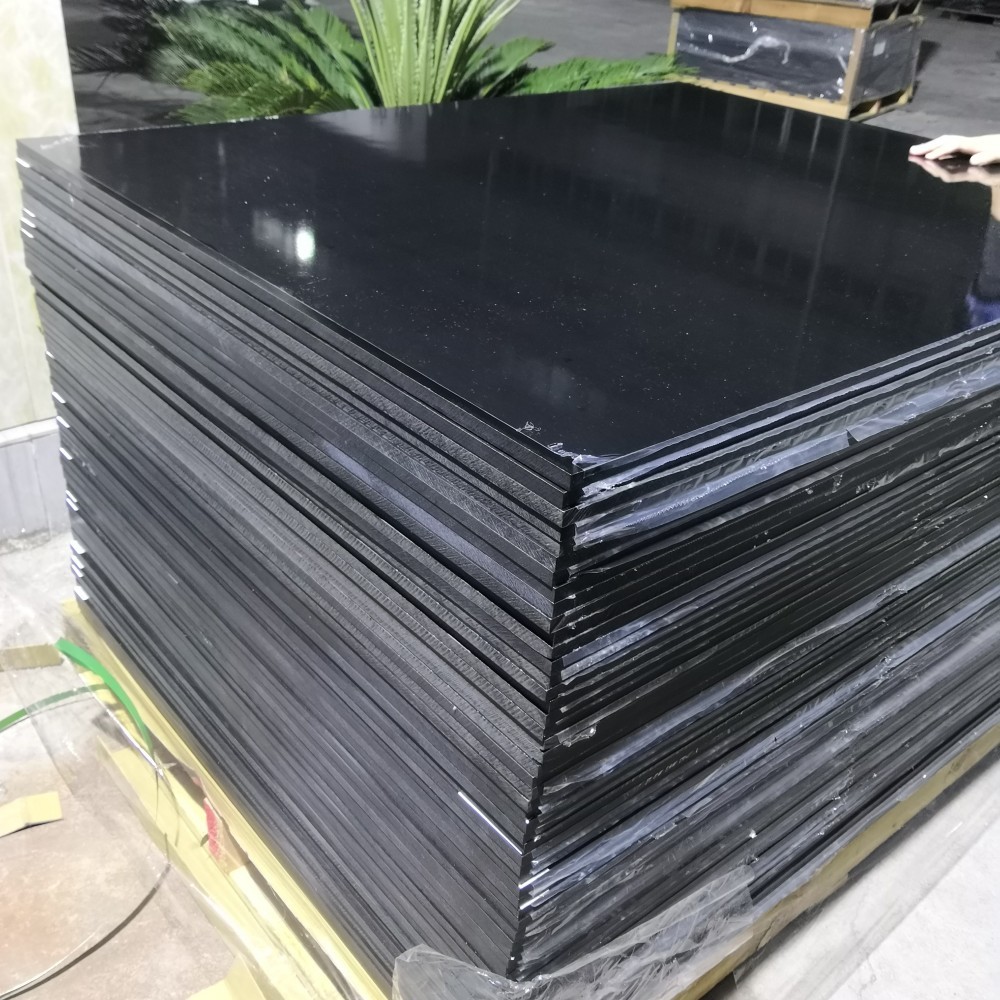

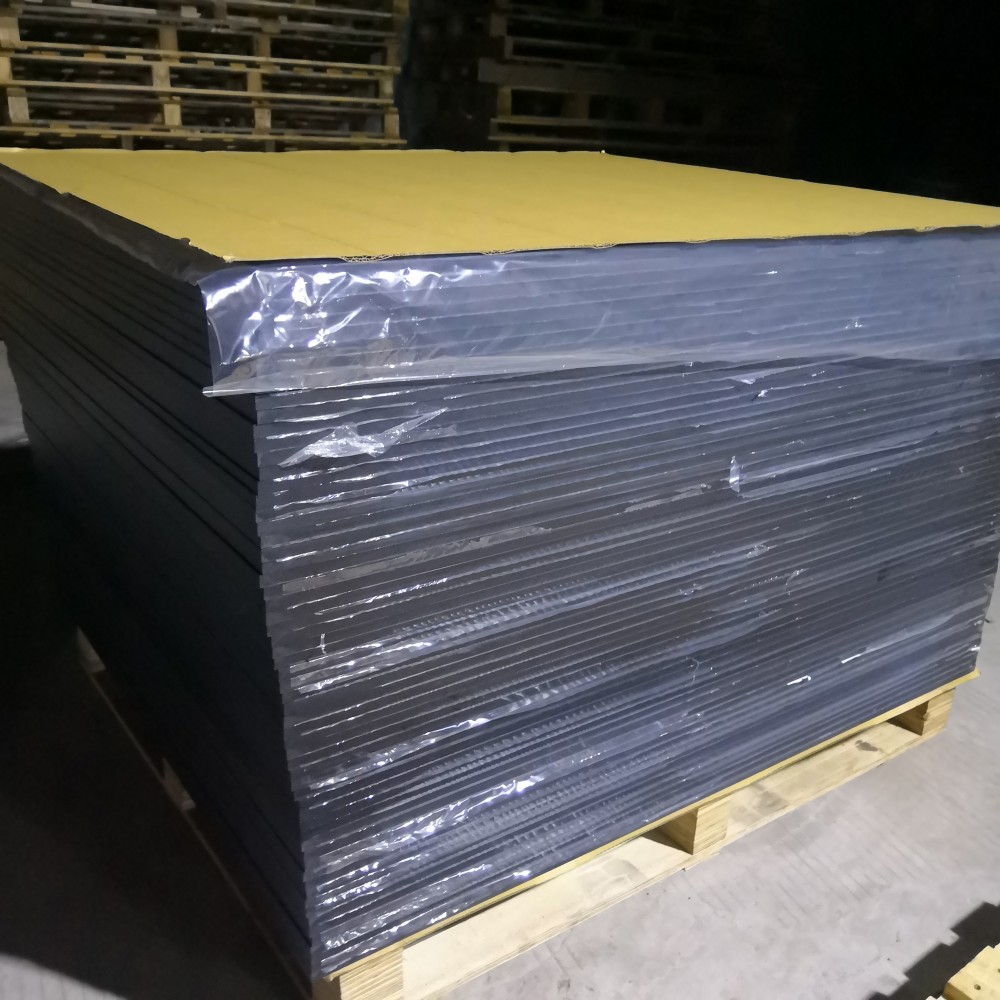

How is the product packaged?

How is the product packaged?

Conventional packaging is pallets for plates, wooden boxes for bars, cartons for processed parts or according to customer requirements.

How long does it usually take to deliver?

How long does it usually take to deliver?

Generally, our standard delivery cycle is 7 to 30 days after receiving the deposit to confirm the order. Please note that the exact time may vary depending on the specific product model you ordered, the complexity of the process, and the quantity ordered. For customized products or large-volume orders, we will provide a more precise delivery schedule when confirming the order.

How does your company ensure product quality?

How does your company ensure product quality?

Product quality is our primary concern. We have established a complete quality control system that runs through the entire process of raw material procurement, production process and final product inspection. We adopt strict standards and ensure that every product delivered to customers meets requirements and standards through methods such as ISO9001 certification and multiple quality inspection processes.

Can you cut or engrave it into the shape we want?

Can you cut or engrave it into the shape we want?

Yes. We have large cutting machines and engraving machines that can be customized.

Certificate Honor

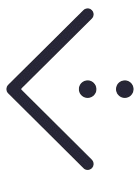

Corporate Atlas

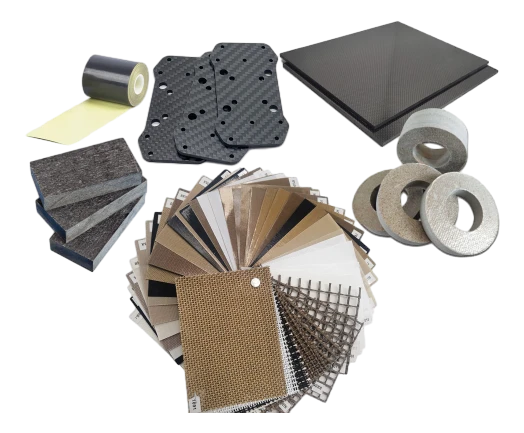

Related Products

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com