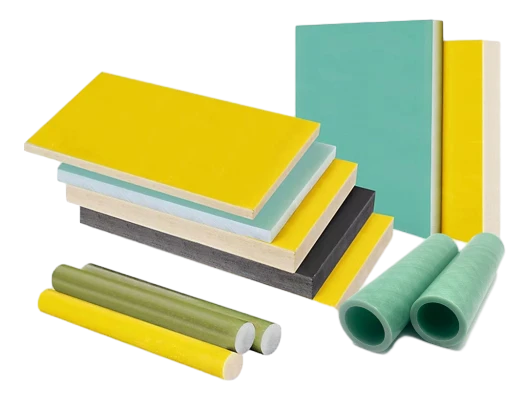

Phenolic Laminated Sheet

keywords:

Phenolic Resin Paper Laminated Bakelite Sheet

Phenolic Laminated Bakelite Sheet is made from high-quality bleached wood pulp paper and cotton pulp paper as reinforcements, combined with high-purity, fully synthetic petrochemical raw materials reacting to form phenolic resin as the resin binder. Among them, phenolic resin is a hard and brittle thermosetting plastic raw material that is formed by thoroughly mixing and heating a certain proportion of sawdust powder, light calcium powder, and other additives with the phenolic resin.

Phenolic Laminated Bakelite Sheet is made from high-quality bleached wood pulp paper and cotton pulp paper as reinforcements, combined with high-purity, fully synthetic petrochemical raw materials reacting to form phenolic resin as the resin binder. Among them, phenolic resin is a hard and brittle thermosetting plastic raw material that is formed by thoroughly mixing and heating a certain proportion of sawdust powder, light calcium powder, and other additives with the phenolic resin.

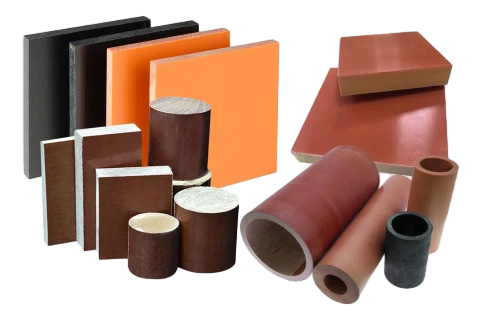

High Quality Phenolic Resin Board Bakelite Sheet

Phenolic Laminated Bakelite Sheet is made from high-quality bleached wood pulp paper and cotton pulp paper as reinforcements, combined with high-purity, fully synthetic petrochemical raw materials reacting to form phenolic resin as the resin binder. Among them, phenolic resin is a hard and brittle thermosetting plastic raw material that is formed by thoroughly mixing and heating a certain proportion of sawdust powder, light calcium powder, and other additives with the phenolic resin.

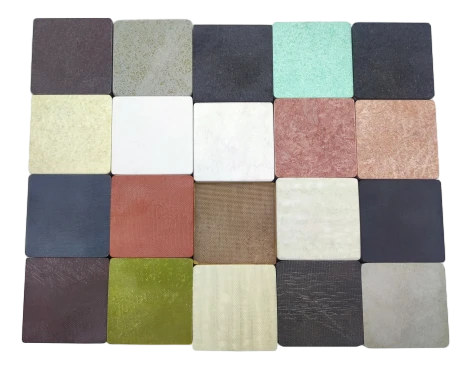

Phenolic Laminate Bakelite Sheet

Phenolic Laminated Bakelite Sheet is made from high-quality bleached wood pulp paper and cotton pulp paper as reinforcements, combined with high-purity, fully synthetic petrochemical raw materials reacting to form phenolic resin as the resin binder. Among them, phenolic resin is a hard and brittle thermosetting plastic raw material that is formed by thoroughly mixing and heating a certain proportion of sawdust powder, light calcium powder, and other additives with the phenolic resin.

Navigating the World of Phenolic Laminated Sheet: Tips and Tricks

Discover essential tips and considerations when working with Phenolic Laminated Sheets to maximize their benefits.

Unveiling the Magic: How a Phenolic Laminated Sheet Works

Discover the fascinating workings of a Phenolic Laminated Sheet and its applications in various industries.

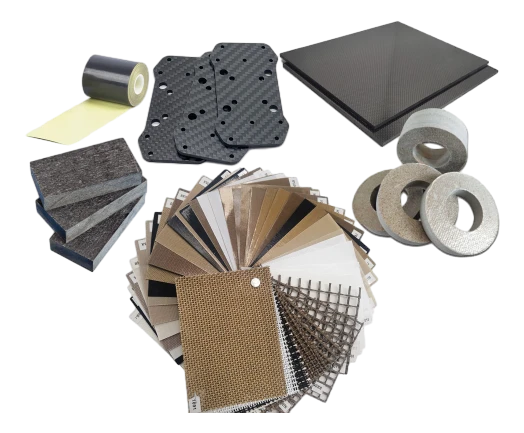

Unveiling the Versatility of Phenolic Laminated Sheets in Everyday Applications

Discover the diverse applications of Phenolic Laminated Sheets in various industries, from construction to electronics.

Discovering the Wonders of Phenolic Laminated Sheets

Explore the unique features and applications of Phenolic Laminated Sheets in various industries.

Why Is Phenolic Laminated Sheet a Top Choice in Insulation Materials

If you're looking for an insulation material that combines durability, stability, and versatility, Phenolic Laminated Sheet is undoubtedly an option worthy of serious consideration. It's more than just a sheet; it's synonymous with quality and trust

Why Is Phenolic Laminated Sheet a Top Choice for High-Performance Insulation

Phenolic Laminated Sheet is a composite sheet made from a phenolic resin matrix and bonded with high-strength fiber materials, manufactured under high temperature and high pressure

How can you choose one that suits you?

Let us assist you!

Our experts will contact you as soon as possible to meet your more needs.

latest products

latest news

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com