Unlocking the Power of Composite Materials in Modern Products

Time of issue: 2025-10-25

What Are Composite Materials?

Composite materials, or Composite materials as they're known in Chinese, are the unsung heroes of modern engineering. Imagine combining the best properties of different materials to create something that's stronger, lighter, and more durable. That's the magic of composites!

A Brief History

Believe it or not, the use of composite materials dates back thousands of years. The ancient Egyptians used a form of composites in their construction, mixing mud and straw to create bricks that were both sturdy and resilient. Fast forward to today, and we've taken this age-old concept and supercharged it with advanced technology.

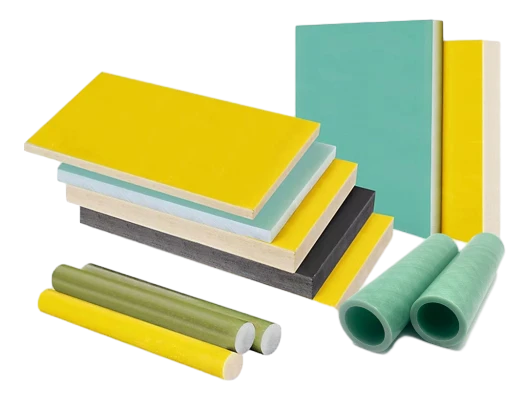

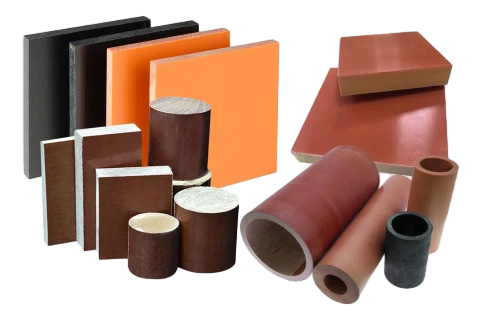

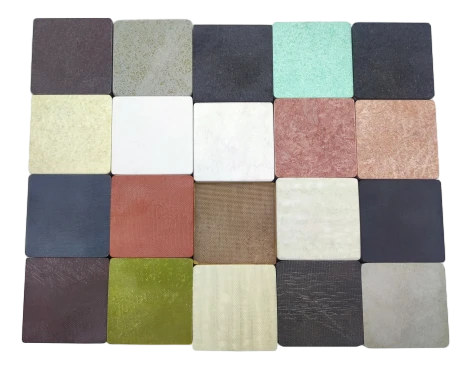

Types of Composite Materials

Let's break it down! There are several types of composite materials, each with its unique properties:

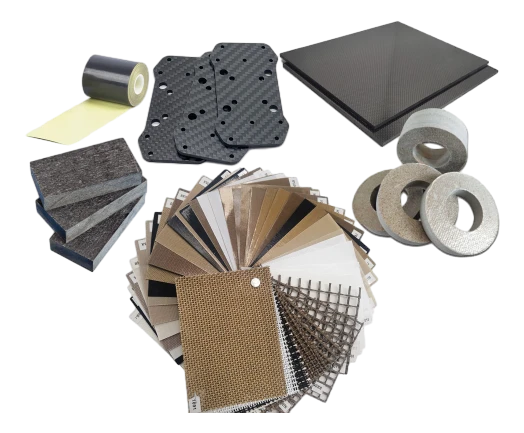

- Fiber-Reinforced Composites: These are made by combining fibers (e.g., glass, carbon) with a matrix material (like epoxy) to enhance strength and stiffness.

- Particle-Reinforced Composites: Small particles are added to a material to improve its overall characteristics, commonly used in plastics to increase durability.

- Laminate Composites: Layers of materials are bonded together to achieve desired mechanical properties, often seen in aerospace applications.

Why Use Composite Materials?

So, why should manufacturers and consumers alike care about composite materials? Well, let's just say they're a game changer! Here are a few reasons:

- Lightweight: Composites can be significantly lighter than traditional materials like steel or aluminum, making them ideal for industries where weight is a critical factor.

- High Strength-to-Weight Ratio: They offer an impressive strength-to-weight ratio, which is why they're favored in aerospace and automotive applications.

- Corrosion Resistance: Many composites resist chemical and environmental damage, leading to longer product life and reduced maintenance costs.

Applications in Everyday Products

You might be surprised to learn just how many everyday products utilize composite materials:

- Aerospace: Airplanes and spacecraft are designed with composite materials to reduce weight and enhance fuel efficiency.

- Sports Equipment: From tennis rackets to bicycles, composites are used to improve performance and durability.

- Construction: Structural components made from composites are increasingly used in buildings, allowing for innovative designs without compromising safety.

- Automotive: Car manufacturers are incorporating composites to reduce vehicle weight, improve fuel efficiency, and enhance safety features.

The Future of Composite Materials

With the rapid advancements in technology, the future of composite materials looks bright. Researchers are continuously exploring new combinations and methods to enhance their properties. For instance, bio-based composites, made from renewable resources, are gaining traction as companies strive for sustainability.

Challenges Ahead

That said, it's not all sunshine and rainbows! There are challenges to overcome, such as:

- Cost of production, which can be higher compared to conventional materials.

- Recycling and disposal issues, as not all composites are easily recyclable.

Conclusion

In a nutshell, composite materials, or Composite materials, are transforming the landscape of product design and manufacturing. They offer a plethora of advantages that can't be ignored. As we continue to innovate and push boundaries, the potential for composites is limitless, paving the way for a more efficient and sustainable future. So, the next time you marvel at a sleek new product, remember the role that these remarkable materials play behind the scenes!

More Information

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com