Revolutionizing Insulation: The Magic of High-Insulation Epoxy Boards

Time of issue: 2025-11-17

Introduction to High-Insulation Epoxy Boards

In the world of modern materials, high-insulation epoxy boards (high-insulation epoxy boards) are making quite a splash! You might be wondering, what's all the fuss about? Well, buckle up as we take a deep dive into the incredible features and applications of these versatile boards!

What Are High-Insulation Epoxy Boards?

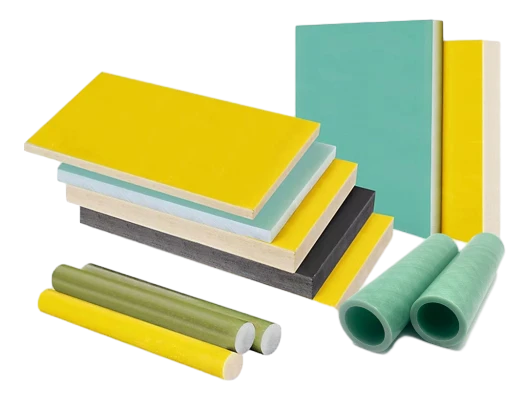

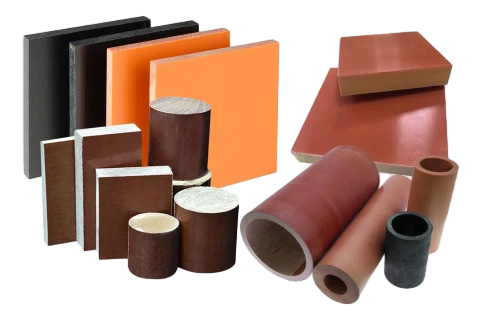

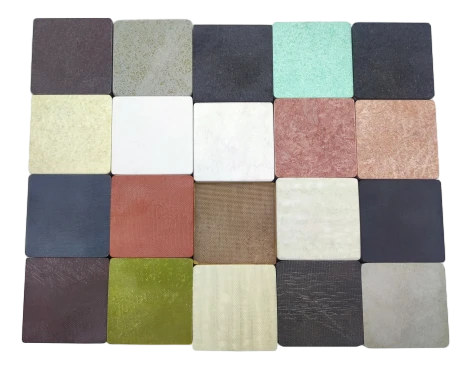

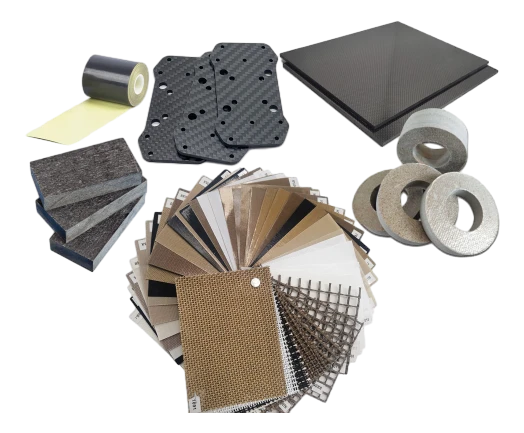

Let's break it down! High-insulation epoxy boards are composite materials known for their excellent electrical insulation properties. Made from a blend of epoxy resin and fiberglass, these boards boast incredible strength and durability. They're not just tough cookies; they also resist moisture, heat, and chemicals, making them the go-to choice for many industries.

Why Choose High-Insulation Epoxy Boards?

Ah, the million-dollar question! Here are a few reasons why these boards should be on your radar:

- Exceptional Insulation: These boards excel at keeping electrical currents contained, ensuring safety in various applications.

- Durability: With their high resistance to wear and tear, you can bet they'll stand the test of time.

- Versatility: From electrical enclosures to circuit boards, they fit in like a glove in countless settings!

- Easy to Work With: Cutting and shaping these boards is a breeze, making them user-friendly for both professionals and DIY enthusiasts.

Applications Galore!

Now, let's talk turkey! You might be thinking, where exactly can I use these high-insulation epoxy boards? Well, here are some popular applications:

- Electrical Engineering: Perfect for creating insulative barriers and substrates in electrical devices.

- Manufacturing Equipment: Often utilized in machinery where high durability and electrical insulation are crucial.

- Automotive Industry: These boards are popping up in electric vehicles, serving as insulators in batteries and control units.

- Aerospace: With their lightweight yet robust nature, they're ideal for aircraft components.

The Manufacturing Process

Ever wondered how these high-performance boards are made? Well, it's no walk in the park! The process involves:

- Mixing: Epoxy resin and hardeners are combined with a fiberglass mesh.

- Forming: The mixture is poured into molds and cured to harden.

- Finishing: Once hardened, the boards are cut and polished to meet specific requirements.

Choosing the Right Board

Not all high-insulation epoxy boards are created equal! When selecting the right board for your project, consider:

- Thickness: Think about the required strength and insulation level.

- Size: Measure twice, cut once! Ensure you have the right dimensions.

- Temperature Resistance: Pick a board that can handle the heat (or cold) of your environment!

Conclusion: The Future is Bright!

In conclusion, the high-insulation epoxy board (high-insulation epoxy boards) is truly a game changer. With their exceptional properties and diverse applications, they're paving the way for innovation in multiple industries. So, whether you're a professional in the field or a DIY enthusiast, consider integrating these boards into your next project. You won't regret it!

More Information

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com