Consumer Electronics & Drones: Innovative Materials for Precision Components

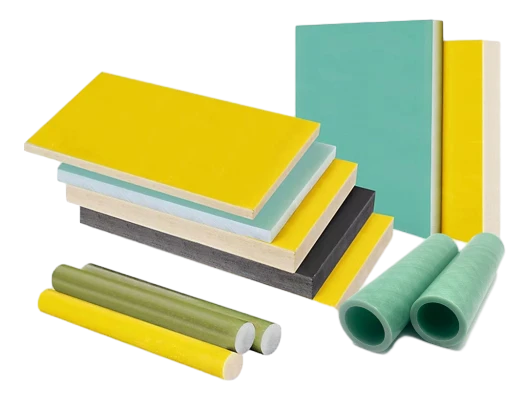

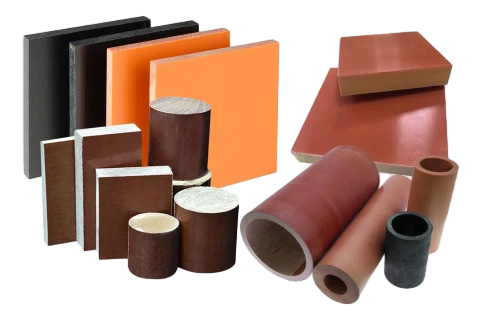

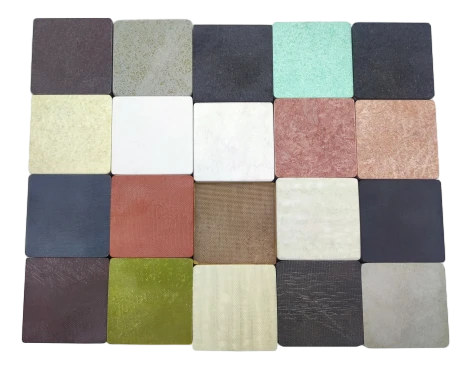

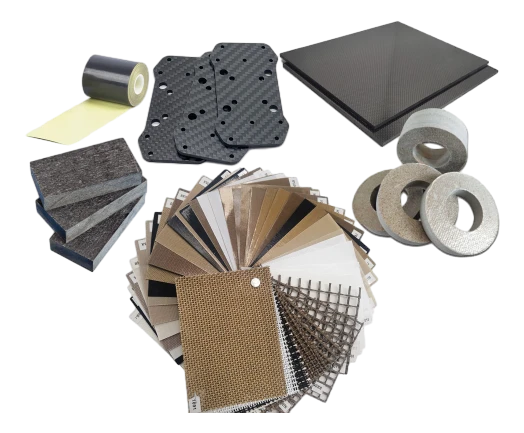

Case Study: Drone carbon fiber frames,Foldable phone hinge reinforcements,Earbud case hinges,VR headset heat sinks,Gamepad motor magnetic shields,Action camera waterproof seals,FPV transmitter PCB substrates,Laptop keyboard light guides Robot vacuum LDS antenna substrates,Vape atomizer cores,Smartwatch heart rate sensor mounts,Tablet electromagnetic shields,Bluetooth speaker diaphragm supports,Camera gimbal counterweights,Drone battery compartment insulation,Projector optical engine brackets,Smart home sensor housings,Wireless charger flux barriers,AR glasses nose pad frames,Drone propeller reinforcement rings

Pain Points Addressed: Pain Point 1: High-frequency signal interference and space constraints → Solution: Dielectric-optimized insulation substrates minimize signal loss and enable miniaturization of precision components (e.g., high-frequency PCB substrates). Pain Point 2: Trade-off between lightweighting and structural strength → Solution: Lightweight yet high-strength insulation frameworks balance weight reduction and mechanical stability (e.g., drone frames, foldable screen hinges).

Applying Case Studies

Contact Us

Company Headquarters

NO.2 Longxian Road, Xinsheng Community, Longgang Street, Longgang District, Shenzhen, Guangdong, China

WeChat QR Code

xyh@xiongyihua-plastic.com

xyh@xiongyihua-plastic.com